Calibration in in the Netherlands

Electromagnetic flowmeters were added to the product range in 1961 with the foundation of the Dutch branch in Dordrecht.

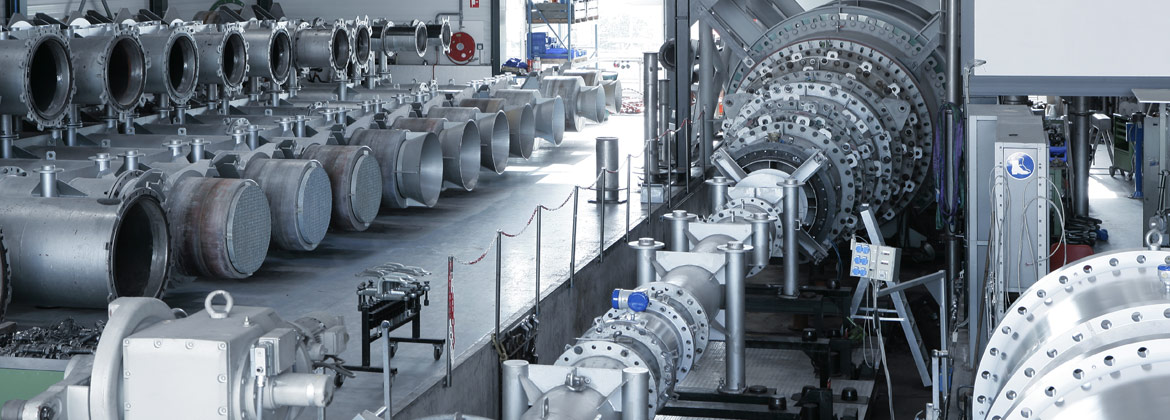

Today, electromagnetic flowmeters and ultrasonic flowmeters from DN 2.5 to DN 3000 are manufactured at KROHNE Altometer, placing huge demands on the calibration rigs. The largest flowmeters are calibrated with the help of the tower seen from a distance. The 44m high calibration tower, which can create volume flow rates up to 30,000m3/h, contains about half a million litres of water. Highly precise position encoders mounted along the entire height of the inside of the tower enable maximum precision when calibrating extremely large measuring devices. This huge engineering feat is put into perspective with the size comparison of the flowmeters shown in figure 4.2.

Smaller nominal sizes are calibrated preferably using piston provers at KROHNE Altometer. The precisely known interior volume of a cylinder is displaced during calibration and compared to the volume measured by the meter under test. A direct comparison of volumes reduces the number of influencing variables, enabling calibrations with extremely small measuring uncertainty. Electromagnetic flowmeters and ultrasonic flowmeters are usually calibrated with water. Special calibrations using other liquids can be carried out with calibration rigs specially equipped for this purpose. Regular comparisons with the Netherlands Metrological Institute (NMI) and comprehensive quality management in combination with long years of experience logged by employees make cutting edge, superior calibrations possible.

Influences in practical use

When you consider the calibration values of a flowmeter, ideally they should not deviate from the measuring values in the application.

References and measurement standards

Calibration usually takes place with the help of a “more accurate” measuring device. This device is referred to as the reference, the measurement standard or superior measurement standard.

Definitions

Any error of measurement detected during calibration as a result of repeat measurements is the so-called systematic measurement error.