Reliable flow and density measurement for consistent raw juice quality and efficient clarification

Efficient measurement solutions for sugar production

Precise process control for one of the world’s sweetest commodities

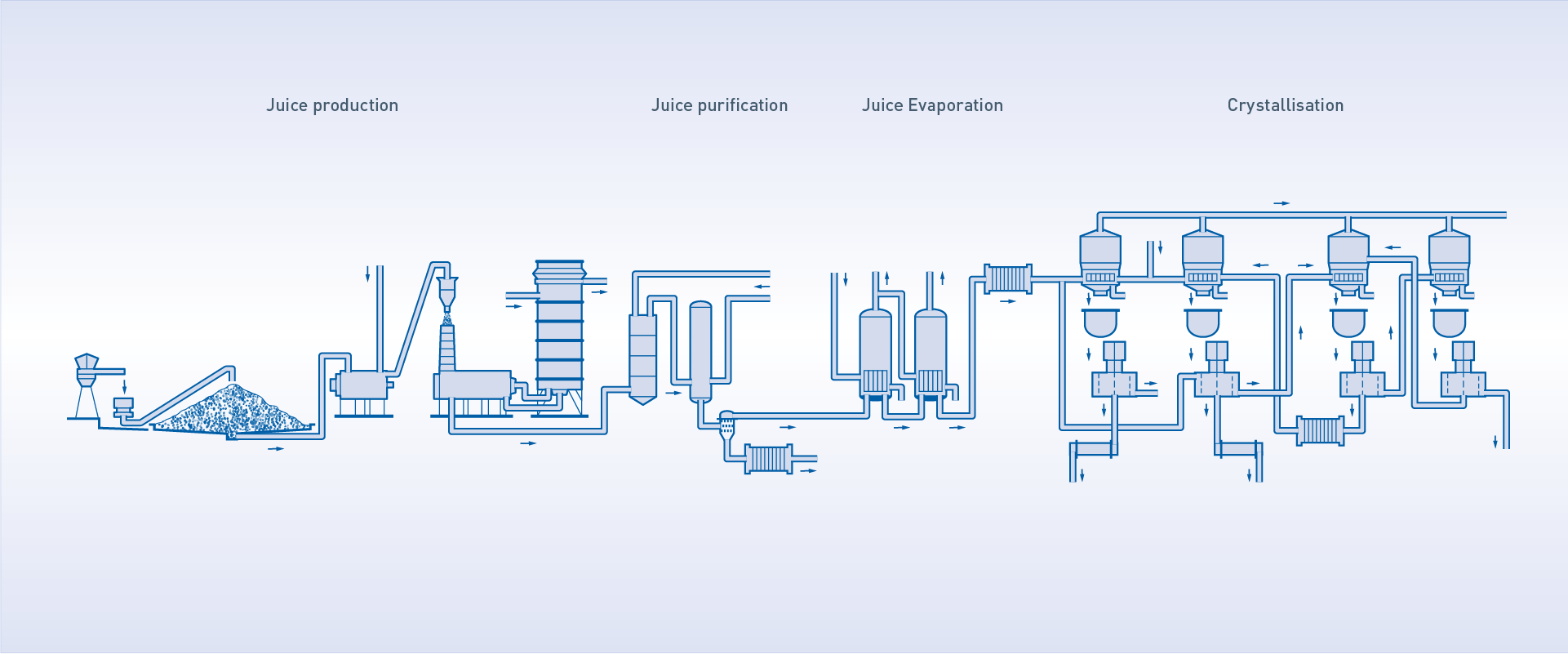

From raw juice extraction to crystallization and refining – the sugar manufacturing process often bears headroom for increased accuracy and efficiency in the various steps.

KROHNE’s industry-leading instrumentation and extensive experience in the sugar industry ensures optimal performance, economic benefits and consistent product quality, even in highly dynamic or abrasive environments. With decades of experience in measurement technology, we provide tailored measurement solutions that support both cane and beet sugar production.

Improving process efficiency has become key in a market where energy costs and sustainability targets are increasingly critical. Our flow, level, pressure, and analytical instruments help reduce waste, minimize downtimes, and optimize energy consumption – all while meeting hygiene and safety standards. Whether you’re looking to modernize existing facilities or plan a new plant, KROHNE supports your goals with reliable technology and application-specific expertise.

Specialists from our dedicated Food & Beverage division are at your disposal to meet your process challenges, worldwide. Being an instrumentation supplier for the Food & Beverage industry for over 20 years, we have gained industry- and application-specific know-how that we have incorporated into our devices and solutions.

Unlock the potential for tighter control of core and costly ingredients

Handling of base ingredients

Measuring your process

Filling/dosing your final product

One of the key challenges in sugar production is to enhance process efficiency and reduce operational costs without affecting product quality or yield. From the extraction of raw juice to the final crystallization stage, each step requires highly accurate and stable measurement – especially when dealing with naturally variable concentrations, temperature fluctuations, and abrasive or sticky media.

KROHNE offers a full range of flow, level, pressure, and analytical instruments tailored to the specific needs of sugar processing. For example, Coriolis meters enable highly accurate Brix and mass flow measurements, even under challenging conditions like two-phase flow or high viscosity. Modern process instrumentation opens new opportunities to optimize cycle times, minimize product loss, and improve control of energy-intensive stages in evaporation. With reliable real-time data for KPIs like °Brix that previously were obtained through time-consuming and offline measurements in the lab, plant operators can reduce manual adjustments and increase the overall consistency and performance of the process.

Enabling measurement technology for sugar production

Your production processes are as individual as your products. KROHNE offers measurement technology that is precisely adapted to your needs and processes. Several special features help optimise your production:

Measurement of raw liquor

The raw liquor has a Brix value of about up to 65 ° as it comes out of the evaporation, at a temperature between 80 and 85 °C.

At this stage of the process, the flow can be measured by an OPTIFLUX 4050 with PFA liner. The IFC 050 is capable of measuring these high sugar concentrations reliably, despite the critically low conductivity in the raw liquor, and thereby functioning as a benchmark for the industry.

Best steam mass-ratio performance

OPTIFLUX, our electromagnetic volumetric flow meter, precisely measures the feed-forward juice at the pre-evaporator and effect evaporator inlets to provide valuable input. This tightens usual tolerances (overshoot, undershoot, too fast or too slow PID, environmental temperature changes…) to an optimum in the so-called steam mass-ratio loop. Precise flow control of the juice, combined with the capability for exact steam supply, enables the highest possible efficiency and avoids unnecessary excess steam beyond the desired °Brix goal in the product after the specific process stage.

Maintaining optimal juice levels to avoid drop drag

OPTIFLEX, our guided level measurement in TDR technology measures level independent of density, foam or temperature or variations in steam supply. The accuracy of ±2 mm keeps the liquid mirror at the ideal level, avoiding sucrose losses due to drop drag or burning of the juice that might occur due to exceeding the set lowest level.

Dosing of lime milk

Lime milk is used in the sugar industry for pH correction and as an auxiliary of flocculation in the bleaching of the sugar solution. Lime milk is an abrasive suspension in which conventional magnetic flow meters have very short lifetime.

The single-tube Coriolis flowmeter OPTIMASS 7000 with transition pieces is the ideal flow meter with an extremely long product lifetime. In parallel to mass flow, OPTIMASS monitors the concentration within a tight tolerance band.

Measuring the layer thickness in the sugar centrifuge

The hot sugar molasses is brought into a centrifuge to reduce the water content. OPTIWAVE 7400 measures the thickness of molasses on the walls of the centrifuge, so in essence, it measures the amount of the wanted, separated concentrate. In addition it also helps to achieve the optimum quantity during filling and almost 100% of the mass in the centrifuge, thereby optimising batches and reducing energy consumption.

By measuring this amount, centrifuges utilize this measurement to switch power off at the optimal point in time in order to use the remaining torque in the ideal way. Significant energy savings are seized.

Steam measurement

Steam is the energy source for the evaporation of juice. The OPTISWIRL 4200 is the perfect device for measuring energy consumption. With its integrated pressure and temperature compensation, it offers gross and net heat consumption for energy balancing.

Thick juice filter

After the evaporation stage, the liquor must pass a filter. A KPI for performance is to measure the differential pressure across the filter. Maintenance free measurement with OPTIBAR DP 7060 stands out from others with a minimum requirement for potential re-calibration, thus requiring less service over the product lifetime.

The OPTIBAR PC 5060 eDP with ceramic measuring cell is a nice alternative for abrasive process media and vacuum conditions due to its mechanical robustness. Compared to a diaphragm seal system, the eDP is less susceptible to ambient temperature changes.

Level measurement silos

The finished sugar granulate is stored in high silos; for this application, the 80 GHz OPTIWAVE radar level transmitter is a perfect match.

The resolution in the spectrum that our 80 GHz measurement brings is not challenged by the dielectric constant, dust or environmental impact.

Tailor-made solutions for your processes

Sugar-production-process including background measuring-points

For sugar production, KROHNE offers precise and robust instrumentation for flow, level, pressure, and analytical measurement – evolved and improved over decades to meet the challenges of handling abrasive media, sticky residues, and variable concentrations in both liquid and solid sugar applications. FMCW radar level transmitters provide non-contact and maintenance-free level measurement in raw juice tanks, syrup evaporators, crystallizers, and refined sugar silos. Even in harsh environments with steam, dust, or foam, these devices deliver reliable results without the need for air purge or mechanical cleaning.

Capacitive point level switches ensure safe and accurate min/max level detection in storage or process vessels – regardless of condensate, buildup, or product stickage. For measuring sugar juice, syrup, or molasses, highly performant Coriolis mass flowmeters are available. These meters provide accurate readings for density, Brix, and mass flow, even under fluctuating process conditions and with entrained air or gas. EGM™ (Entrained Gas Management) ensures the measuring performance remains stable and reliable throughout the process. Heating jackets can be added where needed to support optimal flowability of viscous media.

Our portfolio for the food and beverage industry includes a wide range of instrumentation for non-hygienic, hygienic and auxiliary processes. All devices are designed for CIP/SIP applications, are available with EHEDG, 3A, and FDA approvals, and conform to EC 1935/2004. From electromagnetic and Coriolis flowmeters for dosing and transfer, to radar and ultrasonic level transmitters for both liquids and bulk solids, all the way to MI-005 designed or fully approved loading skids, KROHNE offers a complete and reliable solution package tailored to sugar industry requirements.

Our product portfolio for the Food & Beverage industry

Flow measurement

Flowmeters, flow controllers and flow accessories

Level measurement

Transmitters, switches, indicators and accessories for level measurement

Pressure measurement

Process instruments for pressure and differential pressure applications

Temperature measurement

Assemblies, sensors, transmitters and accessories for temperature measurement

Process analytics

Sensors, assemblies, transmitters, systems and accessories for process analysis

Case studies

Level measurement of condensate in a sugar refinery

Application Note | Food & Beverage

- Level measurement of return condensate

- Reduction of dead zones in the process

- A responsive and reliable measurement

Custody transfer measurement of sugary syrup

Application Report | Food & Beverage

- Measuring system as per MID MI-005

- Mass flow measurement of sugary syrup

- Space-saving installation with straight tube design

Granulated sugar level measurement

Application Report | Food & Beverage

- Storage of sugar of various grain sizes in concrete silos

- Non-contact radar measurement of medium that forms dust

- Automated inventory management of sugar supplies

Level measurement at sugar cane mill

Application Note | Food & Beverage

- Tanks storing sugar juice for the extraction process

- TDR guided radar measurement in steamy atmosphere with harsh temperature changes

- Output data for an automated supply system

Measurement of Brix and mass flow in sugar production

Application Note | Food & Beverage

- Determining the weight and sugar concentration in sugar cane juice

- Measuring without pressure drop or blockage of the measuring tube

- Cost-effective alternative to weighbridges and laboratory analysis

Level measurement in a beetroot hopper

Application Note | Food & Beverage

- Non-contact radar level measurement

- Flow control

- Filling distribution

Measuring layer thickness in a centrifuge

Application Note | Food & Beverage

- Continuous measurement of layer thickness when filling centrifuge

- Controlling the layer thickness during the spin process

- Automated filling process