Applications

This page comprises a selection of sample applications, which demonstrate how KROHNE has solved these industry-specific measurements to the satisfaction of our customers. Whether it is standard or demanding applications with advanced requirements, our knowledge and experience of our customer’s processes is key to addressing these challenges. Using this expertise, allows us to provide the appropriate measuring device, or if required by the application – to engineer complex measuring solutions.

Take a look at a selection of application reports for the hydrogen sector and contact us for your application.

Flow measurement for billing of a hydrogen/natural gas mixture

- Custody transfer flow measurement of a gas mixture with hydrogen (H2) and methane (CH4)

- Re-use of existing natural gas pipeline for H2 transport between industrial sites

- Decrease in energy consumption of 0.15 PJ, 10,000 metric tons CO2 per year saved

Upgrading gas receival stations with standardized electrical cabinets

- Replacing electronic volume converters with modular MI-002 flow computer cabinets

- Cost-effective flow control and data transfer cabinets for a future-proof pipeline network

- Ready for alternative gas mixtures, e.g. natural gas and hydrogen mixtures

High temperature flow measurement of CO2 and H2 from a reactor column

- Improving sustainability and decreasing the carbon footprint of steel production

- Ultrasonic flow measurement to monitor H2 and CO2 separation from flue gases

- Real-time measurement of various gas mixtures at high temperatures

Flow measurement of green hydrogen at a power-2-gas plant (P2G)

- Accurate and consistent information for the grid injection of green gases

- Flow measurement of hydrogen, synthetic methane (SNG), carbon dioxide and natural gas

- Full scope of delivery from one source incl. instrumentation, testing, commissioning and training

Hydrogen flow measurement in tungsten production

- Ensuring consistent hydrogen flow rates for the reduction of hot tungsten oxide to tungsten powder

- Reliable variable area flow measurement at only 40 mbarg / 0.58 psig

- Local and direct reading of hydrogen flow into a reactor furnace without auxiliary power

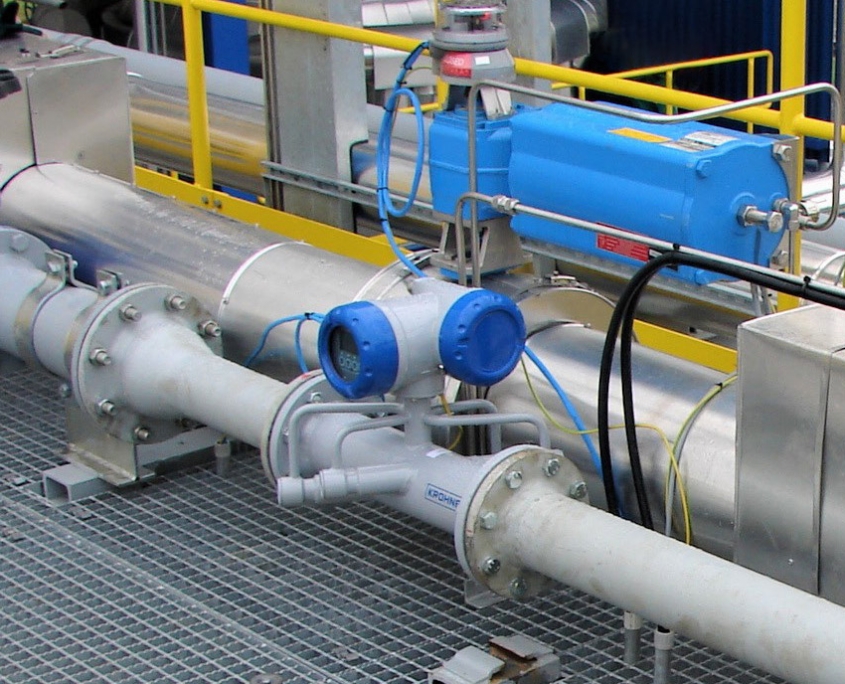

Custody transfer flow measurement of hydrogen

- Reliable and highly accurate measuring system

- Comprehensive solution in accordance with MID MI-002

- Self-monitoring of the measuring system for process optimisation

Mass flow measurement of hydrogen

- Allocation measurement in the production of graphite parts

- Excellent measurement accuracy at low operating density

- Reliable information on gas consumption for improved cost management

Consumption measurement of hydrogen (H2) at a chemical plant

- Ultrasonic flow measurement of H2 from syngas production

- Reliable and safe monitoring of hydrogen supply to production units

- Drift-free measurement over a wide dynamic range up to 1300 Nm3/h

Differential pressure measurement for an ultra-high-pressure application in an oxo plant

- Upgraded high-pressure orifice measurement for aldehyde production

- Retrofitting the entire measurement setup enhanced plant safety and availability

- Hydrogen-ready PN700 (~10000 psi) measuring cell in weight- and space-saving design