Proven technology with new impulses

Latest developments in variable area flowmeters by KROHNE

KROHNE responds to new process requirements of its customers and is continuously improving and expanding its range of variable area flowmeter products. This technology, which has been tried and tested for almost 100 years, still today offers reliable and modern solutions thanks to new impulses.

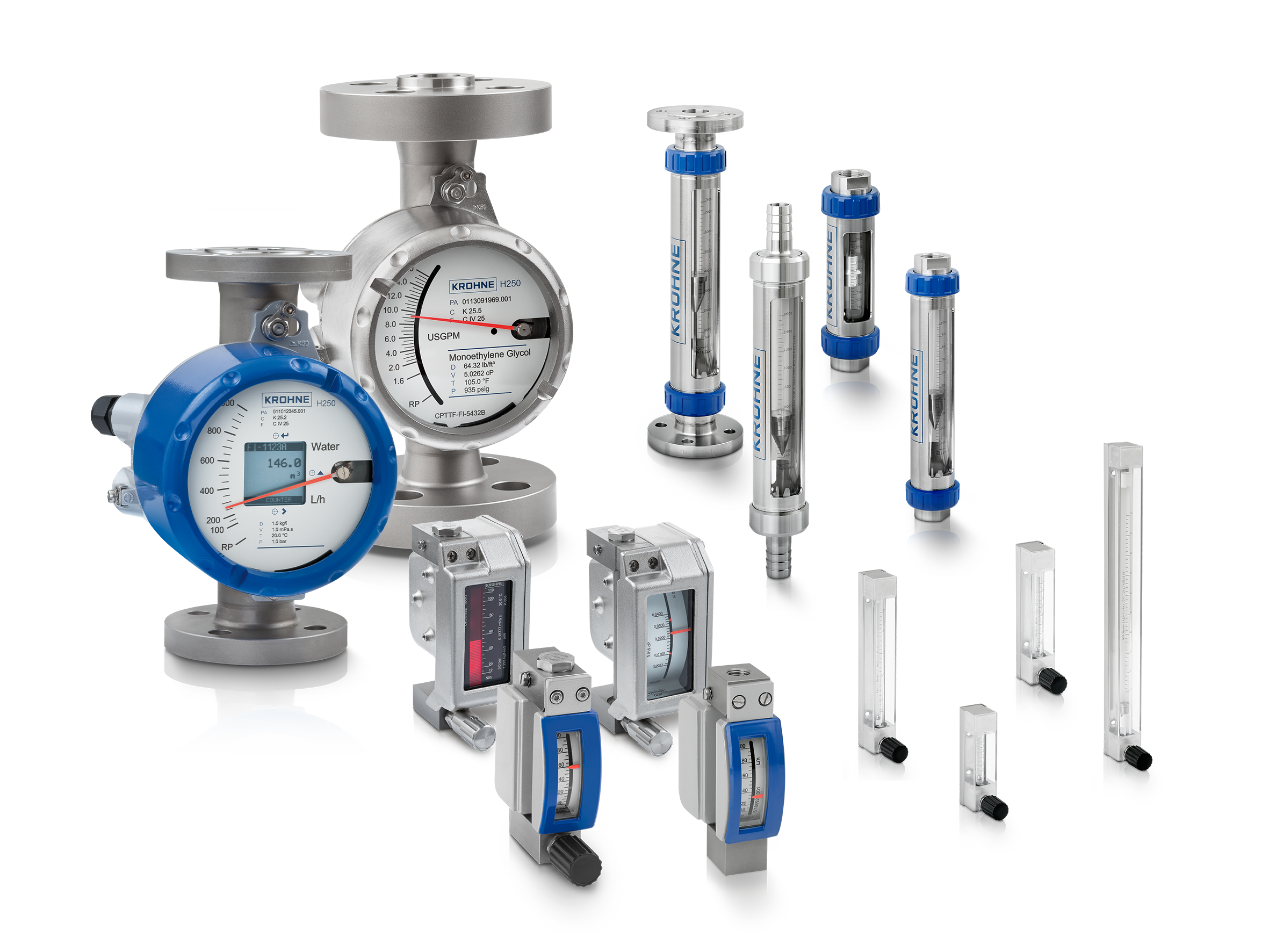

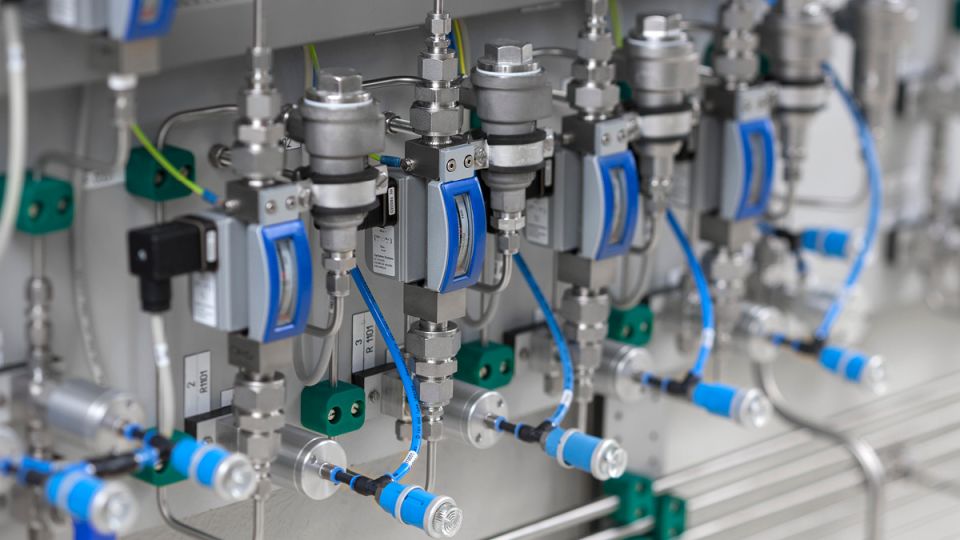

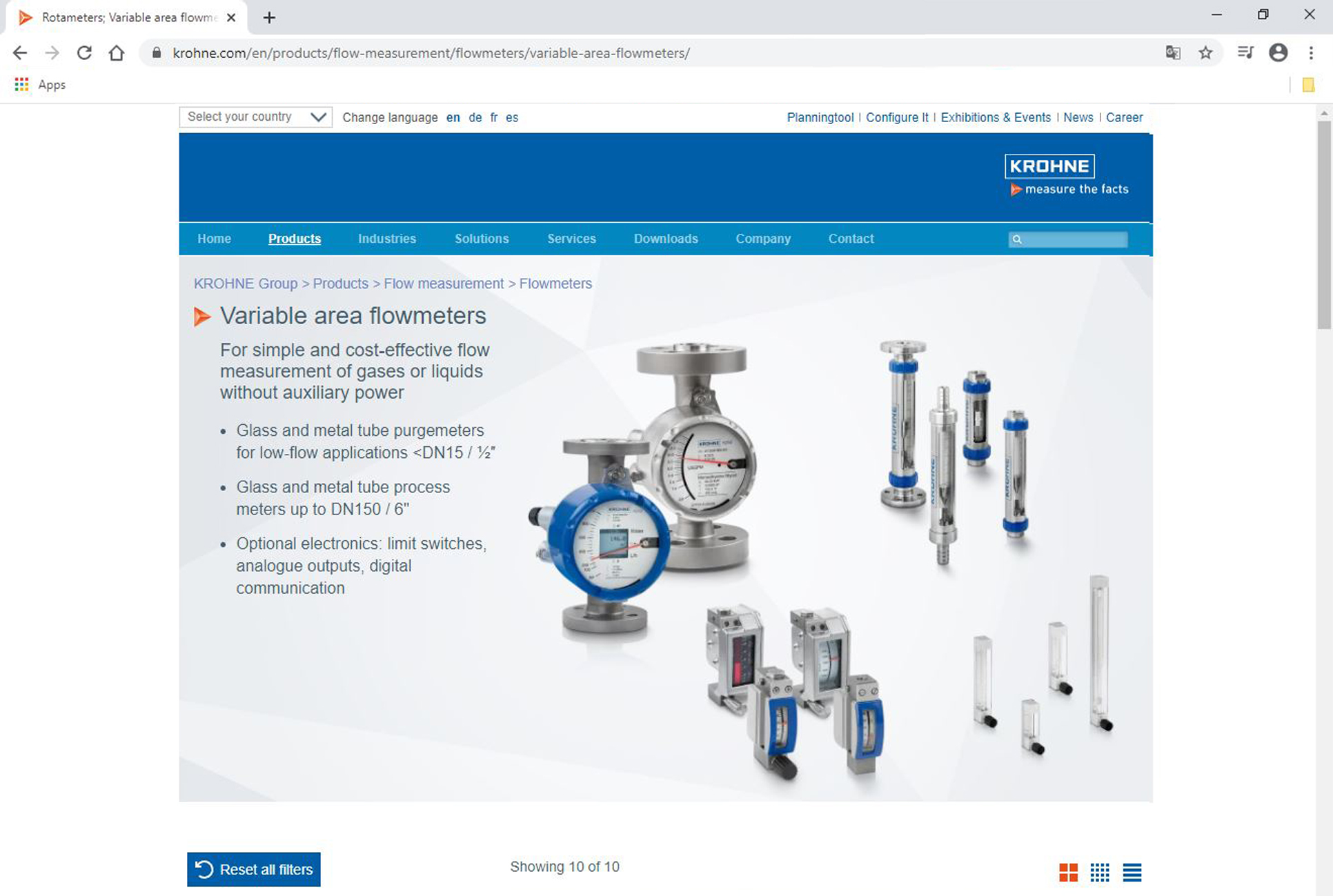

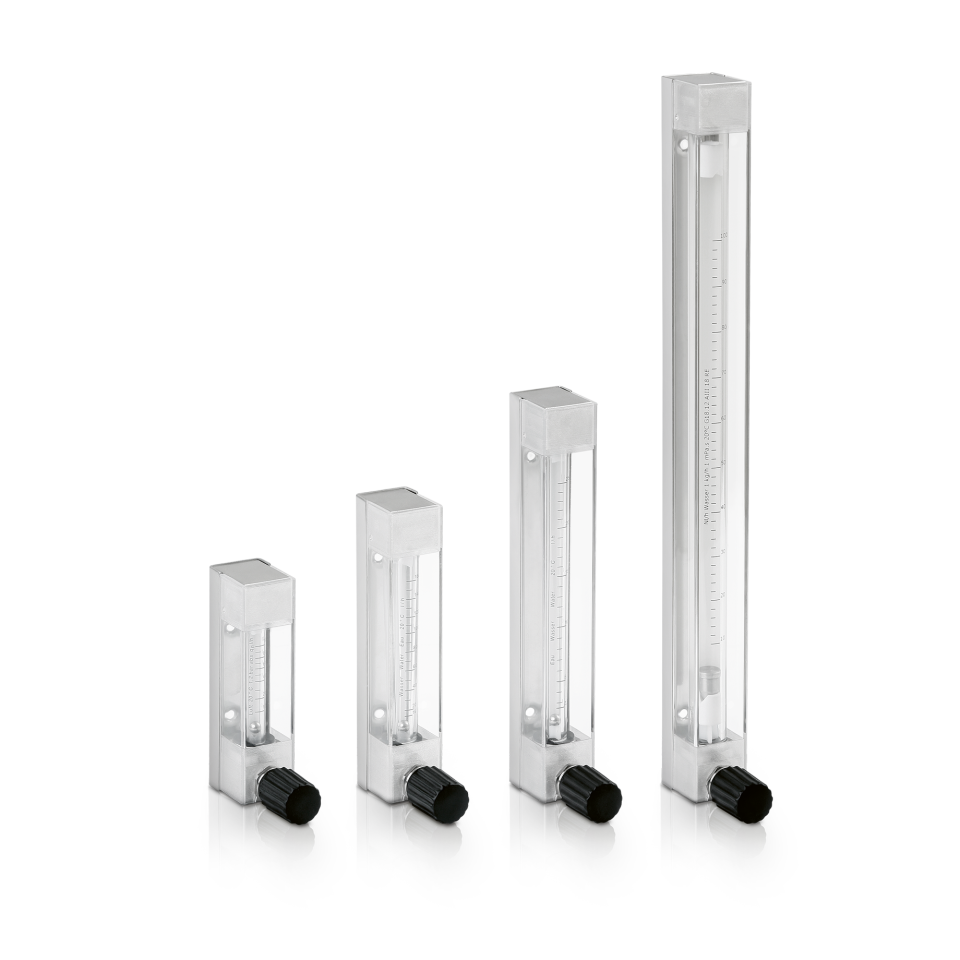

Variable area flowmeters – For cost-effective and easy flow measurement of gases or liquids, even without power supply

Flow measurement by variable flowmeter is always the most common and suitable solution when it comes to measuring low flow rates of clean liquids or gases, and when economy and compact installation take priority over maximum accuracy.

Variable area flowmeters

Highlights

- H250 M40 with Continuous Float Monitoring (CFM) application diagnostics

- Extensive range of SIL2 compliant metal and glass tube devices

- DK32 with new HART® 7 transmitter

- H250 M40 Low Flow for measuring very small amounts

- H250 M40 COM update: HART® 7, FF ITK6, Profibus PA

Typical applications:

- Measuring small amounts of chemicals or additives

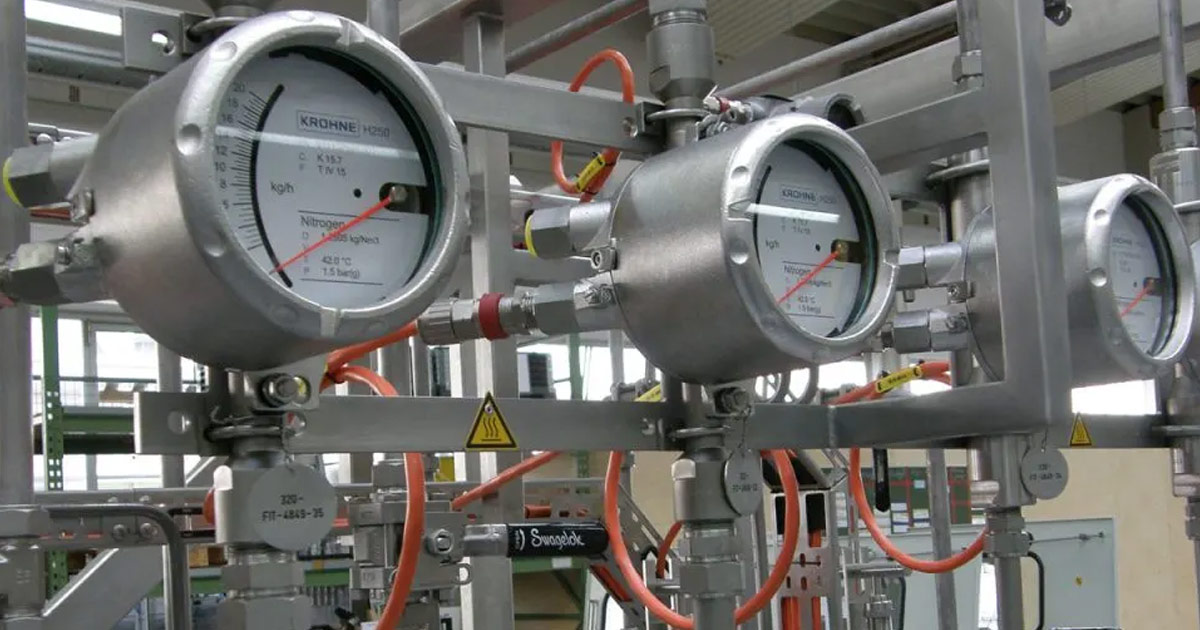

- Inerting with nitrogen

- Monitoring sample flows for process analyser systems

- Monitoring seal gases and barrier fluids for sealing systems

- Injection of corrosion and scale inhibitors

- Continuously dosing purge fluids for measuring systems

- Gas measurement for industrial furnaces and thermal process plants

- Totalising condensate, demineralised or process water

- Measuring air, carbon dioxide or other industrial gases

Even more reliable

H250 M40 – New algorithms increase application reliability

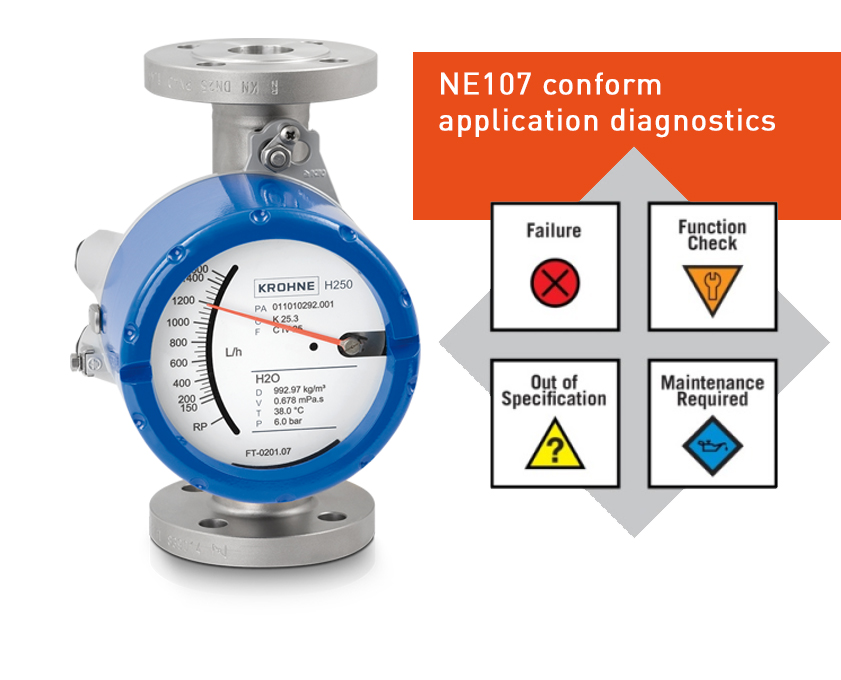

The H250 M40 variable area flowmeter now offers additional application diagnostics as well as device diagnostics to increase application reliability. The new CFM function (Continuous Float Monitoring) monitors the motion pattern of the float using innovative software algorithms.

Notification alerts can be classified from purely informative to device errors with failure current output in accordance with NAMUR recommendation NE107. The intelligent modularity of the H250 M40 means that it can be used to upgrade the functions of existing devices in the field by replacing the 4…20 mA / HART®7 sensor module ESK4A.

Reliable detection of:

- Float blockages because of dirt or pressure bumps

- Compressional vibrations of float in gas measurements

- Pulsating flows in liquid measurements caused by displacement pumps

- Floats incorrectly fitted after maintenance

Even greater choice for safety-related applications

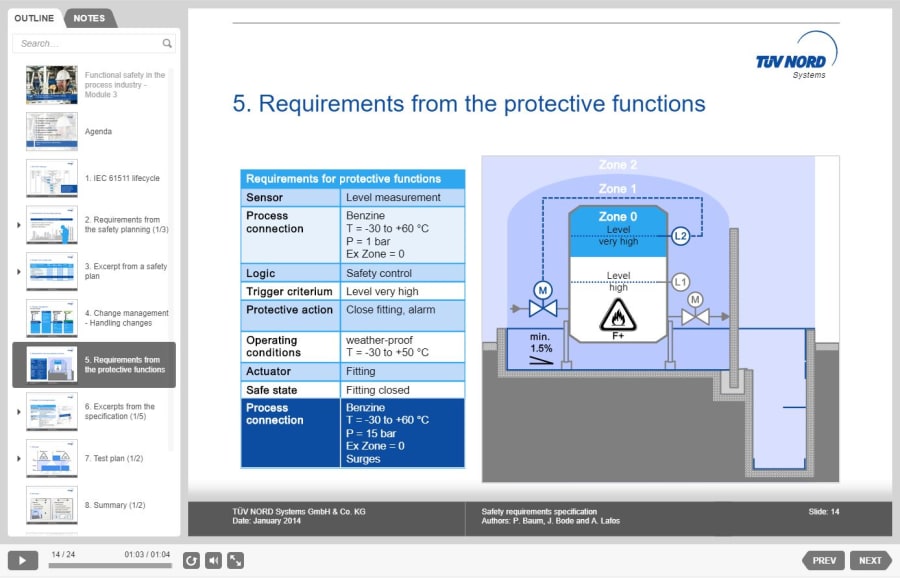

Variable area flow measurement – Entire product range with SIL2 compliance for low-demand mode

KROHNE offers SIL2 compliant models with limit switches for low demand mode for its entire range of variable area flowmeters.

What has for a long time been the preserve of metal tube devices, be it the H250 M40 or the DK32, DK34 and DK37 low-flowmeters, is now also possible for glass tube devices. Both the VA40 glass tube device for simple, industrial applications and the DK46, DK47, DK48 and DK800 low-flowmeters are now available as a SIL2 compliant model for use in safety instrumented systems (SIS).

Monitoring of nitrogen inerting

+ Attend free eLearning course “Functional safety (SIL)“

Ten practical eLearning modules from the companies TÜV NORD, KROHNE, SAMSON and PHOENIX CONTACT will give you an overview of the basic concepts and methods of functional safety.

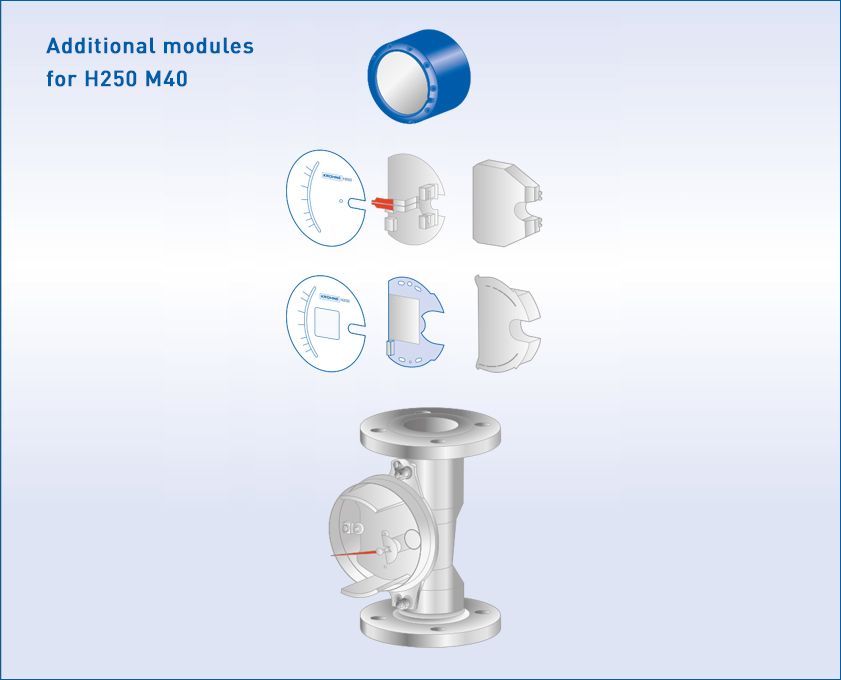

Even easier to handle

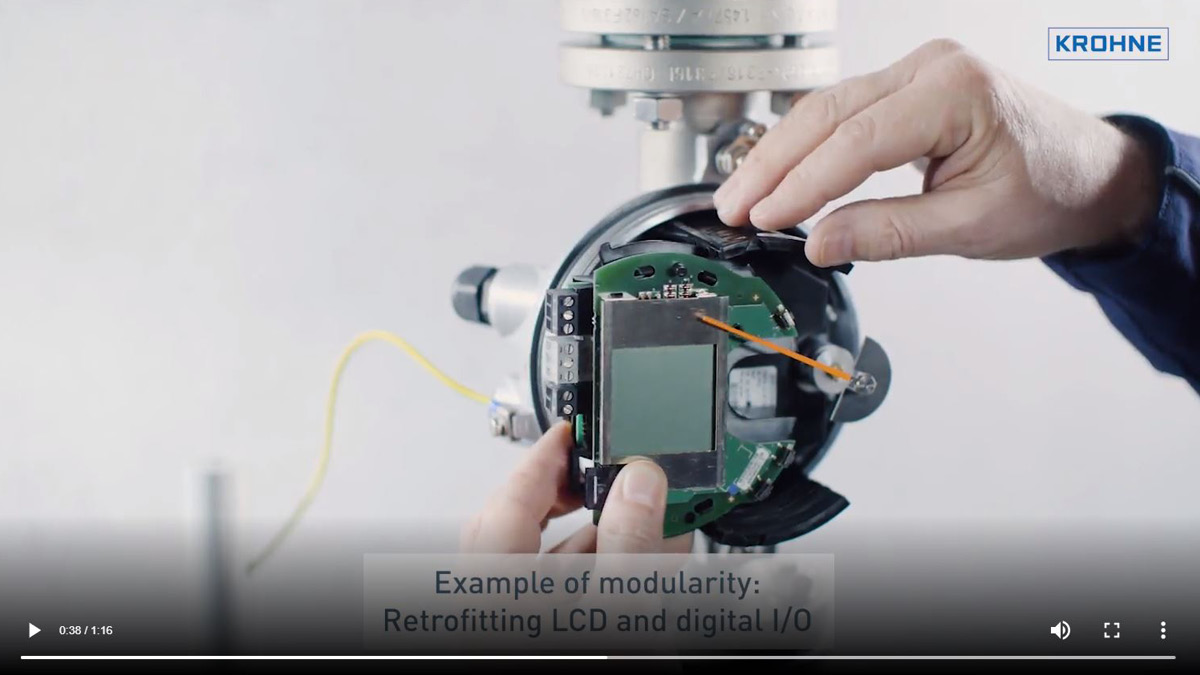

H250 M40 – Application-oriented and always ready for new tasks thanks to intelligent modularity

The H250 M40 is purely mechanical in design and this forms the basis for its flexible uses. Additional electronic modules can be added or replaced at any time. This is how functionality is scaled at will. In this way the device can easily adapt to the changed requirements.

Anything is possible, from analogue flow measurement without auxiliary power to digital integration into a fieldbus system.

Simply screw off the cover, insert the module until it clicks, screw the cover back on and that’s it. There is no need for tools or to interrupt the process for the functionality to be scaled at will. It is just as easy to replace the measuring scale in the event of a change in application.

It couldn’t be easier.

- Limit switches

- 2-wire current output

- Fieldbus communication

- Totalizer with pulse output

- LC-display

Even more powerful

DK32/ESK, DK34/ESK – Greater versatility with the ESK3x transmitter

Part of the range for over 60 years, the DK32/34 series is a real KROHNE classic for low gas or liquid flows in pipes with typical nominal sizes of 4 to 12 mm / respectively 1/8“ to 1/2“. The devices have been continuously improved over decades and adapted to new customer requirements.

The most recent example of this is the ESK3x transmitter, which can be used for DK32 and DK34. It features 4…20 mA / HART® 7 so that it can be incorporated into continuous recording and control processes instead of only monitoring flow limits.

- 2-wire (loop-powered) 4…20 mA

- HART® 7 registered @ FieldComm Group

- Ex-d, Ex-i and Ex-nA/ec, respectively XP, IS and NI

- Conforms to NAMUR NE21, NE43 and NE107

Sample flow monitoring in process analyser systems in the chemical industry

H250 M40 – State-of-the-art communication

The H250 M40 can be used both as a mechanical device without a power supply to display flow locally, and integrated into systems as an electronic device via various signal output options.

The possibilities of digital communication are state-of-the-art thanks to continuous further development: The HART® 7 and Foundation Fieldbus ITK 6 conformity and interoperability have been validated and registered by the FieldComm Group FCG. In addition, practicebased stress tests have been carried out by the manufacturers of common control systems and interoperability has been certified.

The intelligent modularity of the H250 M40 means that functions can be added to existing devices in the field by retrofitting or replacing the communication modules.

Seal gas monitoring for sealing systems on turbo compressors

Profibus PA Profil 3.02

HART® 7.4

Foundation Fieldbus ITK 6.3

Even more flexible

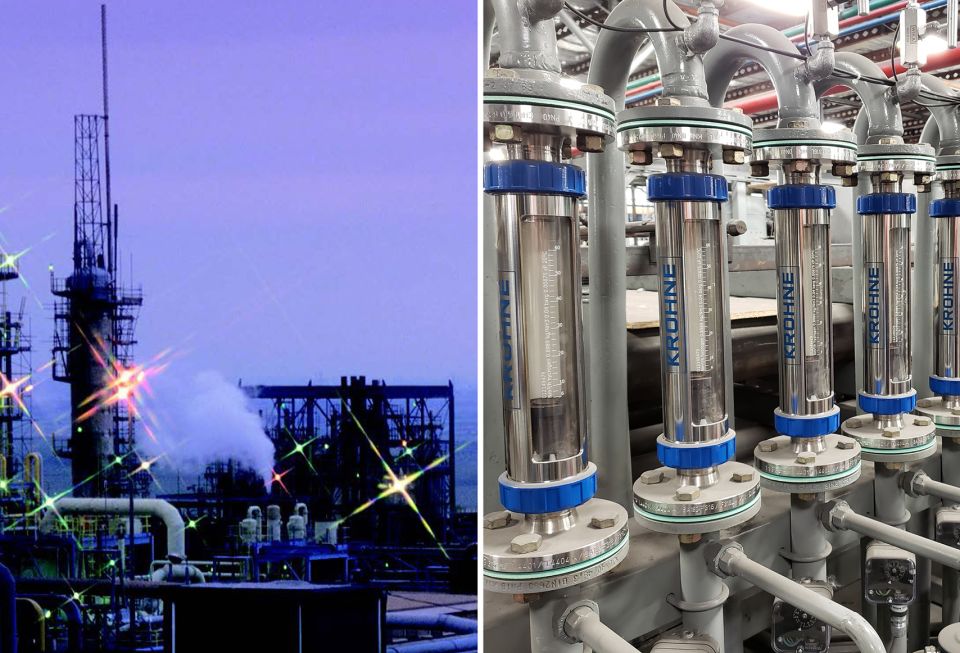

H250 M40 and DK32/34/37 – Global approval for use in hazardous areas.

H250 M40 and DK32/34/37 metal devices from KROHNE offer a universal Ex-design for a wide range of usage in gas and dust explosive areas. Protection types intrinsically safe, non-incendive and explosion-proof accommodate the different regional explosion protection strategies. The devices are approved according to ATEX, IECEx and FM/QPS for the USA and Canada and according to NEPSI for China. In addition, the measuring devices feature other local approvals such as EAC for Russia, INMETRO for Brazil, KCS for Korea and CCOE/PESO for India.

This makes the devices ideal for companies with international production sites or machine and plant manufacturers who market their products internationally and have to meet the local explosion protection requirements.

The worry-free package for hazardous areas:

- Zone 1, Zone 2, Zone 21, Zone 22

- II2G, II2D, II3G, II3D

- Ex-i, Ex-d, Ex-nA/ec, Ex-t

- Class I, Class II, Class III

- Division 1, Division 2

- IS, XP, NI, DIP

H250 M40 – Now also for low flows from 0.15 l/h / 0.04 GPH

The new option for very low flows combines the measuring ranges of purge flowmeters, such as the KROHNE DK37, with the extensive range of electronic options and Ex approvals for the H250 M40.

This broadens the range of applications of the H250 M40 for liquids to 0.15 l/h – 120 m³/h / 0.04 – 32000 GPM and for gases to 16 Nl/h – 2800 m³/h / 0.6 – 100,000 SCFH.

Sample flow processing in the petrochemical industry

Smart service tools

myDevice service suite

As part of the KROHNE Services strategy, myDevice combines a range of smart service tools, which are tailored to the needs of users and operators of KROHNE field devices.

PICK – Device-specific assets via serial number or AutoID

The Product Information Center KROHNE (PICK) gives you complete access to documents specific to your field device thus making the digital twin of your field device available.

Via a serial number or AutoID acc. to DIN SPEC 91406 you get convenient access to all device-related assets such as manuals, approvals and calibration certificates.

ICV videos – Step-by-step video tutorials

There are ICV videos available for H250 M40 to supplement the product manual. These can support and help users save time in relation to:

- Mechanical installation

- Electrical installation

- Commissioning

- Verification

The videos are available in eight languages and can be played on PCs or mobile terminal devices.

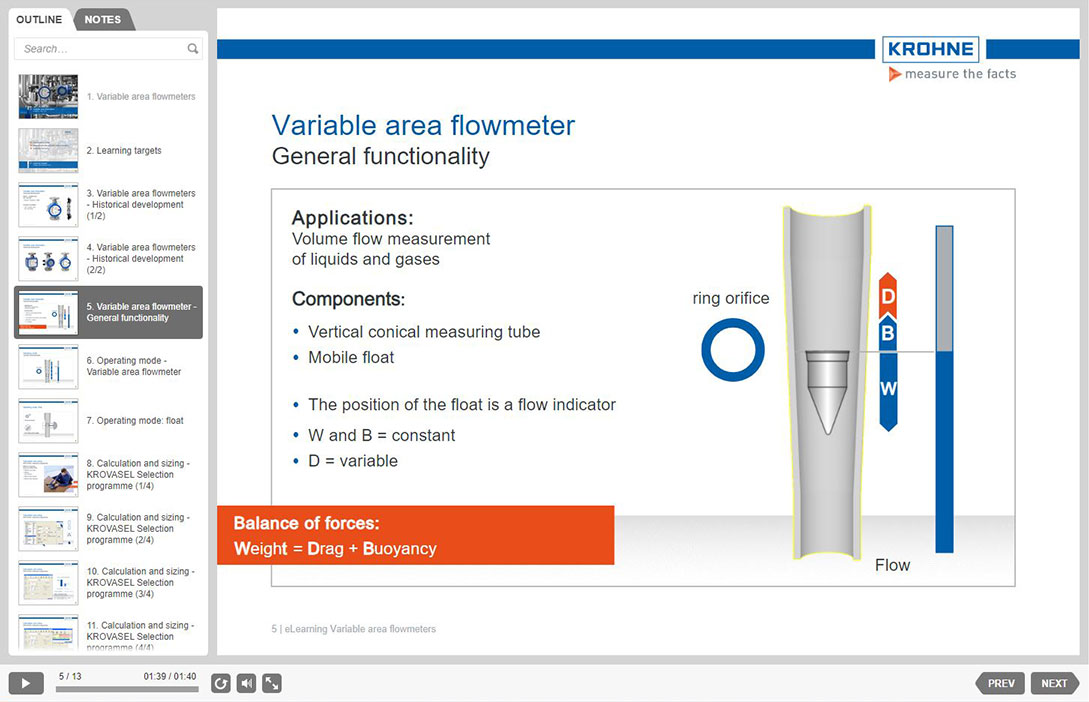

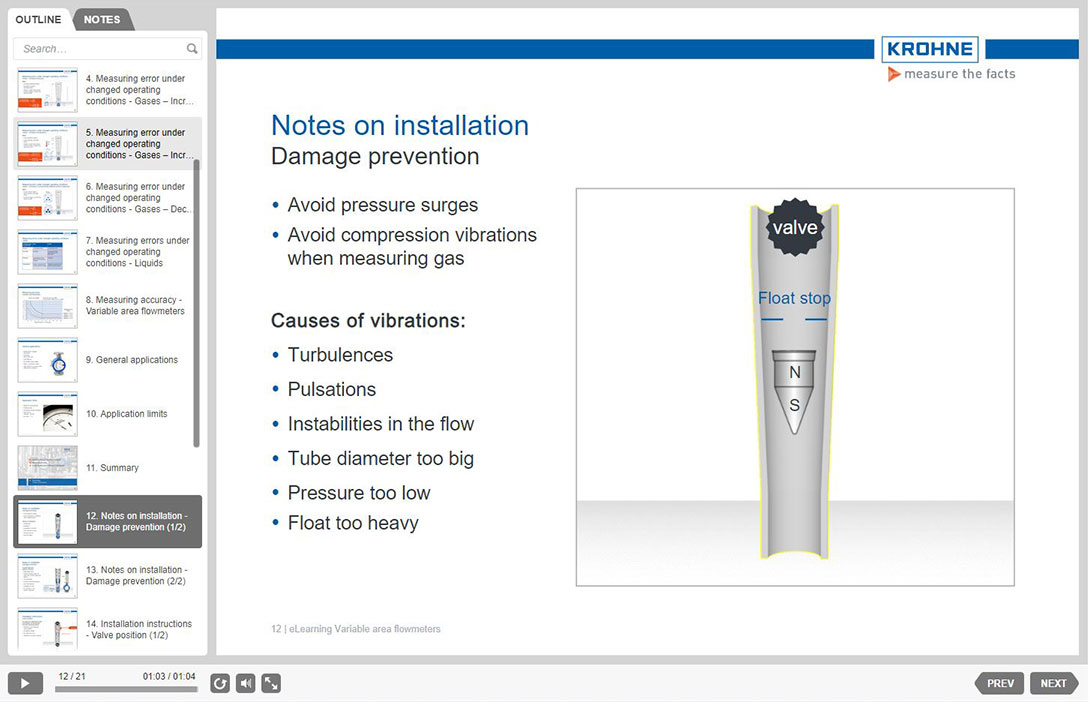

KROHNE Academy online – Online courses available 24/7

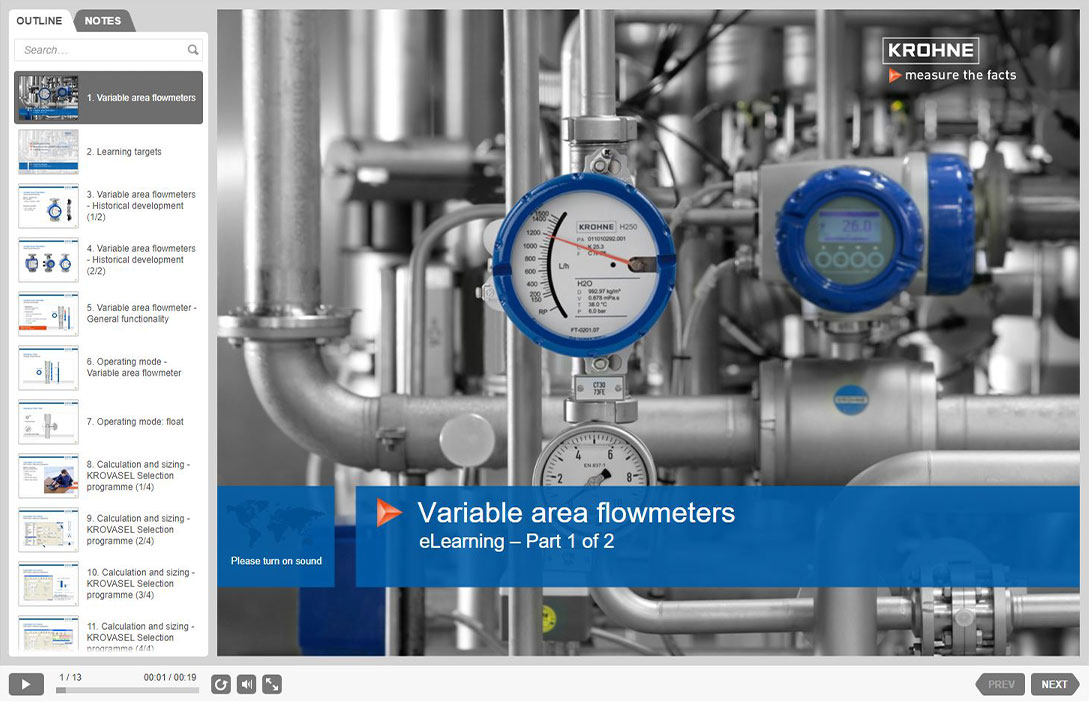

KROHNE Academy online is a web-based eLearning platform focusing on industrial process instrumentation. It comprises electronic training courses with full audio, explaining measuring methods without relating them to specific manufacturers as well as live webinars.

For example, the „Variable area flowmeters“ course covers the measuring principle and the functioning of these measuring devices as well as measuring accuracies and general properties.

Further information

Variable area flowmeter product pages

Get an overview of all our variable area flowmeters, technical highlights, target applications and product variants

H250 M40 microsite

Get more detailed information, sample applications and associated technical data

Case studies

Take a look at our application library, which gives many success stories about variable ares flowmeters in the field

Free eLearning course „Variable area flowmeters“

The „Variable area flowmeters“ course covers the measuring principle and the functioning of these measuring devices as well as measuring accuracies and general properties

Free eLearning course „Basics of gases“

The „Basics of gases“ course provides an introduction to the topic, including a description and examples of different gas types and specific gas properties

Free eLearning course „Basics of explosion protection“

The „Basics of explosion protection“ course explains basic physical, technical and legal principles as well as building regulations for explosionproof devices and examples

Variable area flowmeters

H250 M40

Variable area flowmeter for liquids and gases

H250 M8

Variable area flowmeter for liquids and gases

DK37 M8M

Variable area flowmeter for advanced low liquid and gas flows

DK32/34

Variable area flowmeter for low liquid and gas flows

DK46/47/48/800

Variable area flowmeter for low flow gas or liquid applications and sample flow monitoring

VA40

Variable area flowmeter for basic applications

VA45

Variable area flowmeter for low pressure gas applications

K20

Variable area flowmeter for basic water applications

Contact us

Head office KROHNE Group

www.krohne.com

Are you located in the US?

us.krohne.com

You can contact us directly via email.