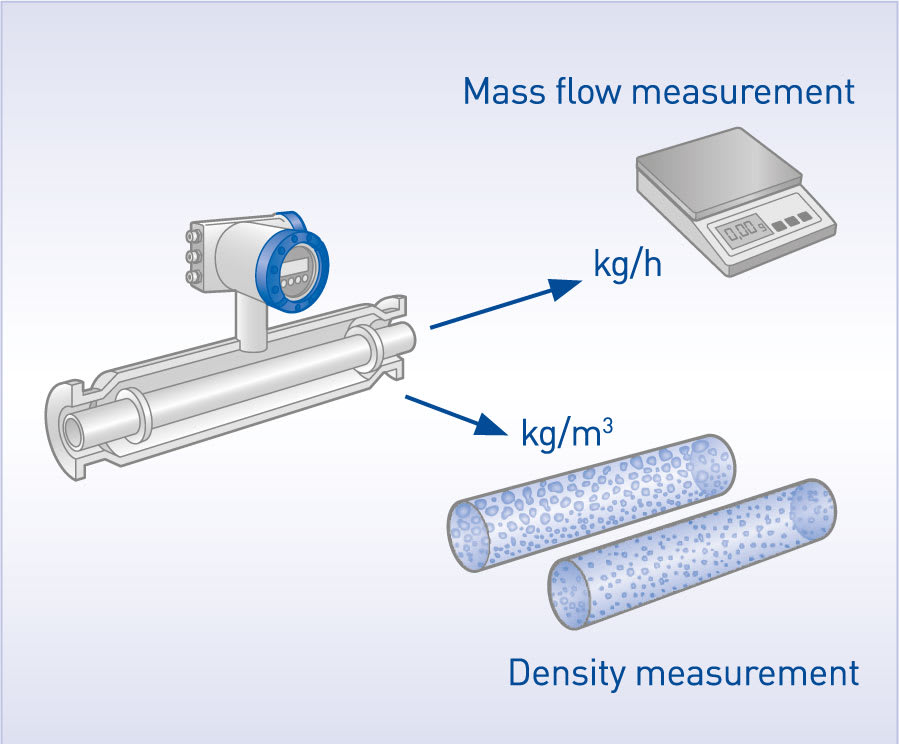

Mass, volume flow, density and concentration measurement of liquids and gases

Leading Coriolis technology by KROHNE

OPTIMASS mass flowmeter series suitable for all process and custody transfer (CT) applications

KROHNE has over 3 decades of experience, developing the most innovative Coriolis meters. When it comes to selecting a flowmeter, the OPTIMASS series covers the entire range of high performance and high reliability Coriolis devices for all relevant applications. Our engineers have developed a family of meters from small to large, suitable for simple or demanding applications such as highly corrosive media or multi-phase flows with different gas fractions and complex flow conditions, for high pressure, cryogenic temperatures or high temperatures.

All meters have been designed to reduce constraints on the user with regards to installation – simply follow good engineering practice to obtain the desired results. Within the system, the diagnostics software monitors a series of process and auxiliary values in order to ultimately confirm the condition of the process medium. The devices allow secure wireless access via Bluetooth®, even in safety-related applications, furthermore they are equipped with the groundbreaking EGM™ (Entrained Gas Management) technology to maintain operation over a wide range of gas volume fractions and complex flow conditions.

Follow this page to discover the many advantages of the OPTIMASS product portfolio.

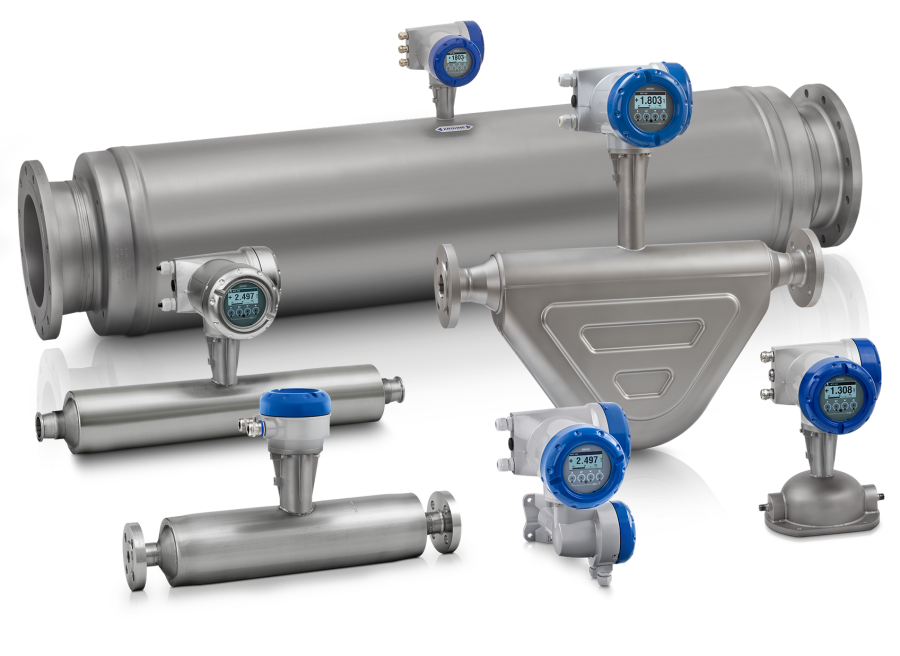

Complete portfolio of mass flowmeters

The OPTIMASS series includes a complete portfolio from DN01 to DN400 (1/25″ to 16″) with wide pressure range and temperature range from -200°C to 400°C (-328F to 752F). KROHNE offers superior mass flowmeters with straight and bent tube designs, so the customer can choose the best meter for their application.

We offer a unique straight tube design for minimal pressure drop, highly viscous, corrosive and slurry applications. It´s the only single straight tube meter available in titanium, stainless steels, HC-22 and tantalum. The superior bent tube design is suitable for cryogenic, high temperature and extremely high pressure applications.

- Mass, volume flow, density and concentration measurement of liquids and gases

- Various designs: from twin bent to single straight tube

- From DN01 to DN400 (1/25″ to 16″)

- Wide pressure range

- Wide temperature range -200°C to 400°C (-328F to 752F)

The technology-led products are designed for a wide range of complex and demanding environments, where accuracy and reliability are essential. The OPTIMASS series is suitable for all process and custody transfer (CT) applications, especially for the measurement of liquids, gases and liquids with entrained gas.

Some examples:

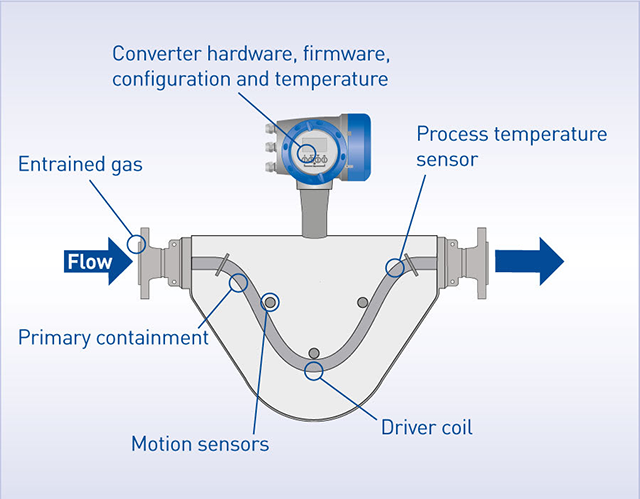

EGM™ Entrained Gas Management technology

EGM™ was developed for OPTIMASS Coriolis mass flowmeters to overcome problems caused by air or gas entrainment in a liquid. Powerful control algorithms allow the flowmeter to maintain operation over a wide range of gas fractions and complex flow conditions, even during a complete transition from a pure liquid phase to a gas phase and back. Mass flow and density measurements remain stable and continuous, which has been demonstrated in batch/ loading/ empty-full-empty applications. Even during a complete transition from a pure liquid phase to a gas phase and back, i.e. from 0 to 100% gas content, the device will continue to operate. EGM™ (Entrained Gas Management) is a standard feature on all OPTIMASS flowmeters with MFC 400 converter and presents a number of advantages for your process:

- Meter maintains operation over a wide range of gas volume fractions and complex flow conditions up to 100% entrained gas

- Excellent repeatability for mass and density

- Ideal for batching and loading with empty-full-empty applications

- Reliable detection and indication of 2-phase flows, air/gas entrainments

OPTIMASS with EGM™ can cope with slurries containing gases, and highly viscous fluids with plugs of gas entrainment. EGM™ also helps to overcome problems of flow regimes where increased viscosity and the relative different velocity of the liquid and the gas affect the flow regime.

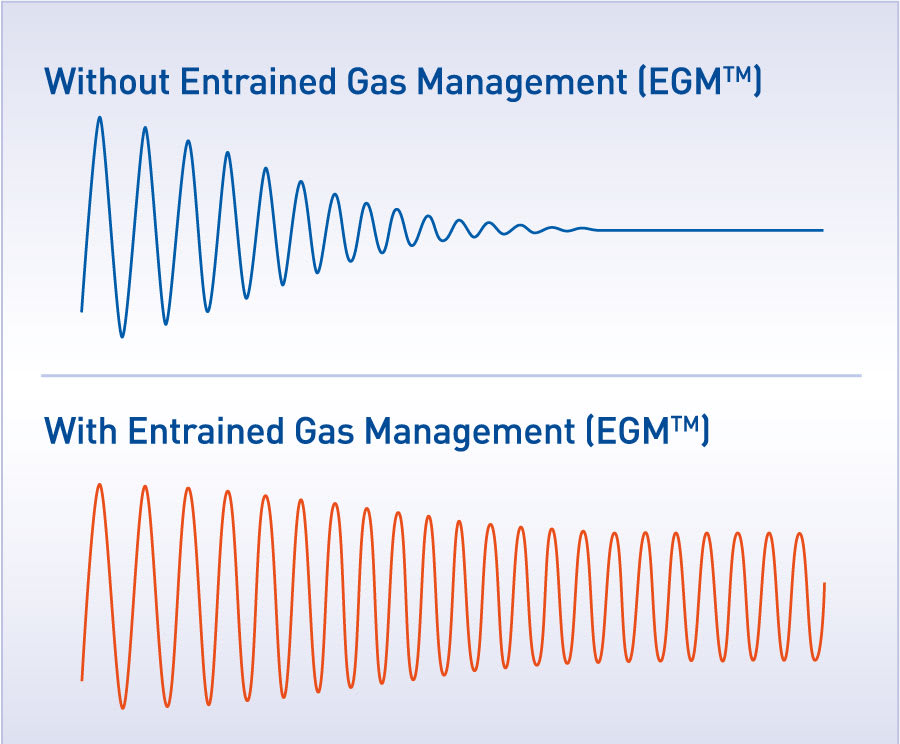

Gas entrained in the liquid dampens the regular oscillation of the measuring tubes, and as the gas content increases, the oscillation can come to a complete stop. To overcome this, KROHNE has developed powerful control algorithms that allows the meter to maintain the oscillation and continues to operate even with complex flow regimes.

Even during a complete transition from a pure liquid phase to a gas phase and back, i.e. from 0 to 100% gas content, the device won‘t stop the operation.

Coriolis flowmeters can measure the mass flow, volume flow and density of any fluid, whether it is aerated or not. Density measurement of single-phase fluids is common practice, but for traditional meters it becomes challenging, when there is entrained gas.

In many applications where entrained gas is present, meters with EGM™ show excellent performance and repeatability for process control, batching, loading, offloading and transfer measurement.

Superior performance for all process applications

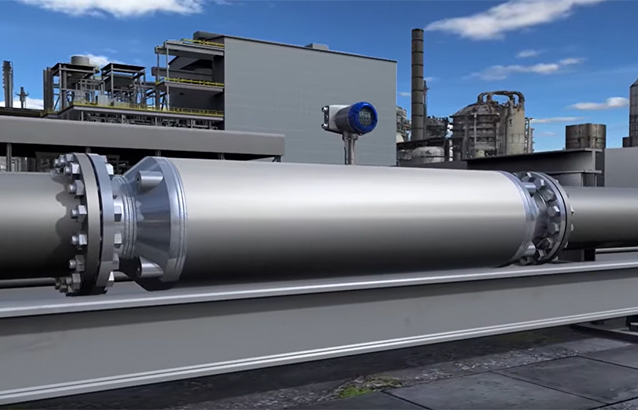

When it comes to selecting the correct flowmeter, the OPTIMASS series meets the needs of industrial users worldwide. KROHNE offers superior straight and bent tube design Coriolis flowmeters in sizes 1 to 400 mm (1/25” to 16”) covering flow rates from 0.3 to 4600000 kg/h (0.011 to 169021 lb/min). All applications are covered including custody transfer and problematic applications such as highly viscous media, non-homogenous mixtures, media with solid content and entrained gas. With no straight inlet/outlet requirements and a compact design, OPTIMASS flowmeters place minimum constraints on installation, making it easy for you to select the best meter for your application.

OPTIMASS 1400

For universal applications and process control

OPTIMASS 2400

Dual or four straight tube design for bulk flows for custody transfer up to DN400/16″

OPTIMASS 3400

For low flow and dosing applications

OPTIMASS 6400

The standard high-performance meter for the process industry, up to DN300/12″

OPTIMASS 7400

For advanced applications, with single straight measuring tube

Centre of excellence for mass flow technology

The centre of excellence for Coriolis mass flowmeters is located in Wellingborough in the United Kingdom. KROHNE launched the first commercially available single straight tube Coriolis meter and holds many patents that make possible the natural evolution of unique designs.

KROHNE has over 3 decades of experience in developing the most innovative Coriolis meters. Our state-of-the-art R&D and manufacturing facilities are focused on continuous improvement of the product design & quality. Ongoing research and development plays a crucial role in shaping and innovating the evolution of the OPTIMASS range. Each product is continually tested to global standards, to provide highest possible product excellence and reliability. Beside R&D and production we attach special importance to pre and post sales customer support, with in-house, on-site and remote training available.

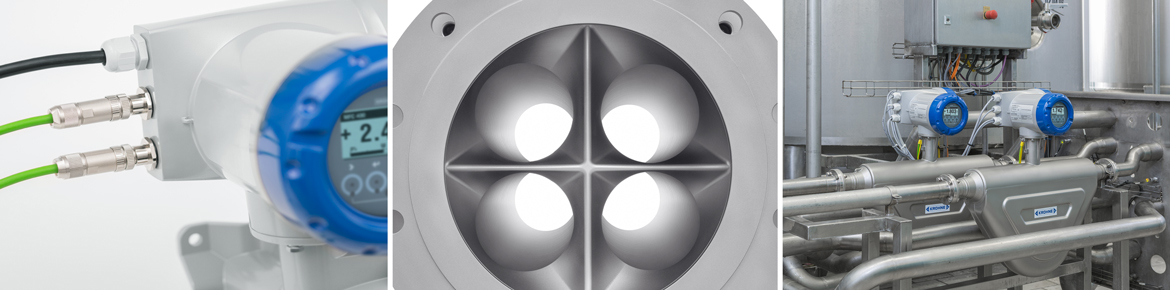

Communication: All options available

Complementing the communication options of HART® 7, FOUNDATION™ fieldbus, PROFIBUS® (PA and DP) and Modbus, the MFC 400 signal converter of the OPTIMASS series is available with EtherNet/IP and PROFINET I/O option. This means all OPTIMASS x400 Coriolis mass flowmeters can be equipped with Industrial Ethernet communication. All measuring, process and diagnostic information from the meter is therefore available in real time via a single communication channel, which leads to many benefits for our customers:

- Easy integration with other systems

- Latest communications protocols available

- Safe and secure communication

- Drivers and software free of charge: no subscription required

Calibration: Certainty you can count on

Calibration is one of KROHNE’s core areas of expertise. When you buy a KROHNE product, you will get a measuring device that performs accurately with low uncertainty under real process conditions. KROHNE is the Coriolis manufacturer with the largest calibration rigs on the market, accredited according to ISO/EN 17025. The lowest extended uncertainty for large flow rates is 0.017% up to 2000000 kg/h (73487 lb/min).

We can calibrate the largest Coriolis mass flow meter up to 83% of the nominal flowrate with an unique procedure at three temperatures. The new calibration rigs allow the OPTIMASS 2400 S400 / 16 inch Coriolis mass flowmeter thereby to be calibrated for flows up to its nominal capacity. Our meters can be calibrated and certified according to various standards such as OIML, Measuring Instruments Directive (MI-002 & 005), and comply with API and AGA.

The world´s first SIL certified Coriolis flowmeters with Bluetooth® communication

All OPTIMASS flowmeters with the MFC 400 converter are now available with secure Bluetooth® communication. Therefore we present the world´s first device that allows wireless operation in a safety-related application. Using the new OPTICHECK Flow Mobile app on mobile devices or FDT/DTM on laptops commissioning, parameterisation, verification, performance monitoring and application parameters can be managed on-site via a Bluetooth® connection (<20 m65.6 ft) – ideal for devices installed in inaccessible areas or EX Zone 1 (Class>

OPTICHECK DTM for advanced device verification and commissioning

- Usable with any FDT frame application from the control room or on site

- Advanced verification (level 0,1) without process interruption

- Detailed reports for proof test documentation of safety loops acc. to IEC 61508/61511, and for quality management systems (ISO 9001)

Novel features for safety-related applications

OPTIMASS flowmeters with the an MFC 400 converter are the world´s first SIL certified Coriolis devices with Bluetooth® communication, furthermore, the converter makes some extra features available throughout a wide range of applications in Safety Instrumented Systems.

- Fully developed for safety applications acc. to the latest IEC 61508 2010 standard

- Diagnostic coverage of >96 %

- Diagnostic test interval of less than one minute: this allows use in SIL 2/3 applications or in continuous demand mode, the highest specified levels of operation

- SIL 2/3 software certification ensures the lowest possible number of systematic software errors

- Fail-safe bus topologies and other hardware safety-relevant features

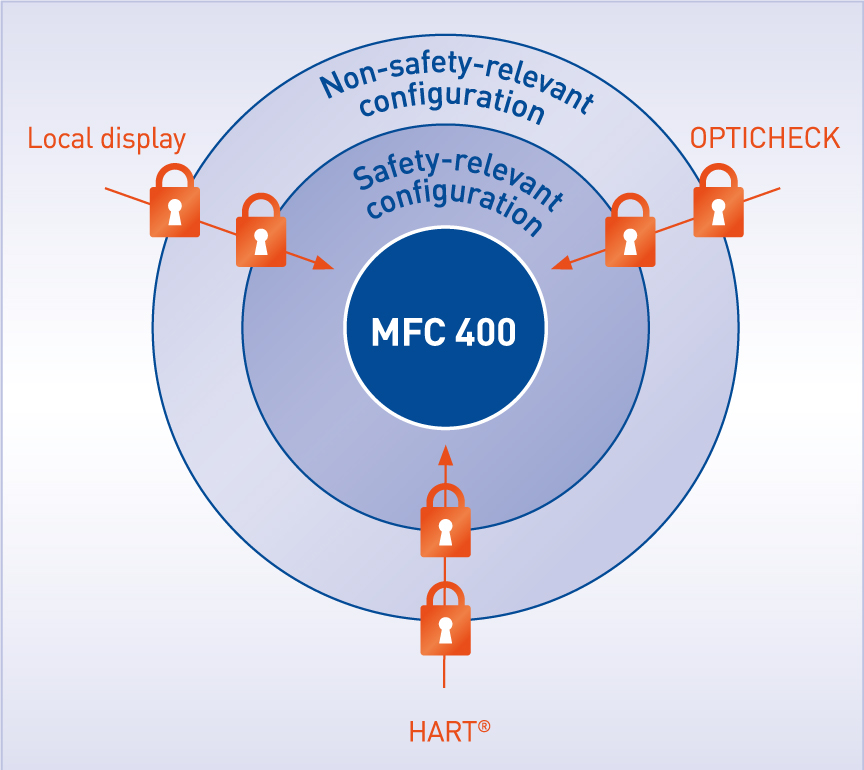

The MFC 400 converter software provides the most secure and versatile authentication concept for all remote access, fully certified via TÜV Rheinland. The MFC 400 allows safety-relevant data to be changed via HART® signals using an FSK modem, even from the control room.

This requires that all access levels are fully password protected, no matter whether the configuration is carried out remotely via HART®, via the local display, or via the OPTICHECK service tools.

Developed acc. to IEC 61508/61511, the OPTIMASS Coriolis flowmeter series is designed to meet the highest safety as well as security standards. In order to achieve diagnostic coverage of >96 %, all flowmeters have integrated continuous signal monitoring, redundant references and calibrations.

Redundant storage of all device configuration data allows the converter to be replaced at any time without the need for manual reconfiguration: This means higher safety and less effort for the end-user.

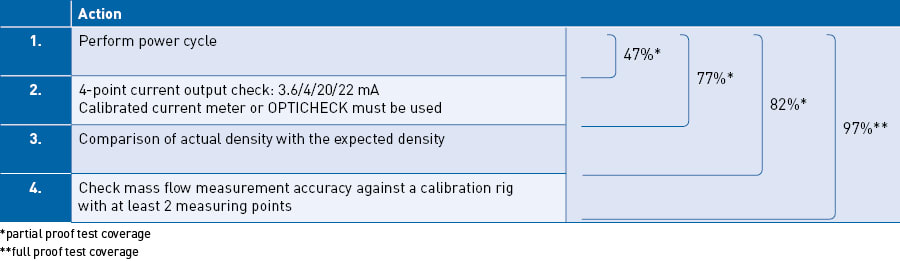

A partial proof test procedure for the OPTIMASS series has been developed in conjunction with TÜV Rheinland. Proof test coverage (PTC) of up to 82 % is thus provided without the need to remove the device. This ensures the safe operation of any safety-relevant function and helps to justify the lengthening of full proof test intervals.

Contact us now!

Do you need further advice in choosing the right Coriolis device for your application?

Contact us now using the form

Or:

Direct contact US:

info@krohne.com / +1 978 535 6060

Direct contact UK:

info.uk@krohne.com / +44 1933 408500