Measurement of media with air inclusions – as may occur during the delivery of raw materials

Advanced measurement solutions for Chocolate production

Reliable but gentle process measurement of your indulgent delicacies at the industry’s lowest shear rates

A high-quality product often means a challenging production process. Manufacturers of chocolate and cocoa products have special requirements, starting with the input logistics through to the measurement accurate to the gram. KROHNE has a dedicated Global Industry Division which accepts these challenges and offers individual measurement solutions.

In the chocolate manufacturing process, achieving high quality, safety and efficiency is the priority: this sets highly challenging demands on the measurement technologies used. Please accept our invitation to meet in person, or online, to discuss your process improvement potential. Let us help to enable the evolution of your manufacturing process with our industry and application know-how and high-quality products.

Specialists from our dedicated Food & Beverage division are at your disposal to meet your process challenges, worldwide. Being an instrumentation supplier for the Food & Beverage industry for over 20 years, we have gained industry- and application-specific know-how that we have incorporated into our devices and solutions.

Unlock improvements to give faster production and tighter control of core and costly ingredients

Handling of base ingredients

Measuring your process

Filling/dosing your final product

One of the biggest challenges in the manufacture of chocolate, ice cream and other sweets and cocoa products is to increase efficiency and to lower costs without compromising the texture of the final product. Besides precise flow, pressure, temperature and analytical instruments, KROHNE can supply units with direct heat tracing of the measurement tube. Liquids with a solids content or entrained gas can be measured precisely, even despite high viscosity, for example with cacao butter, changes in viscosity, or where there are sensitive temperature conditions. Modern technologies face challenges like the deficits of two phase flow conditions, revealing big potential for process optimisation and reduction of losses.

Enabling measurement technology for Chocolate production

Your production processes are as individual as your products. KROHNE offers measurement technology that is precisely adapted to your needs and processes. Several special features help optimise your production:

Measurement of media with air inclusions – as may occur during the delivery of raw materials

Our Coriolis flowmeters with EGM™ entrained gas management maintain operation and high repeatability of measurements – despite the presence of fibres, solids or air entrainment in the slurry, dough or any other kind of mash. Mass flow and direct density measurement of aerated products is already possible in the mixed stage.

Measurement of highly viscous products and avoiding the time and manpower challenges of concentration and mass flow measurement

Our Coriolis mass flowmeters also allow inline concentration measurement directly in the process. Based on the operating frequency, the density is determined in real time and serves as a further indicator of continuous quality assurance. The accuracy of the measurement can be as accurate as 200g in 1000kg or in other words, two bars of chocolate more or less when weighing an average car.

Heat tracing of temperature sensitive media

KROHNE Coriolis flowmeters can be delivered with factory fitted heating jackets. The jackets are welded directly to the sensor body, achieving an optimum heat transfer, through direct contact with the heating medium. The result is an integrated heat tracing of temperature sensitive media and the prevention of changes in the fluid viscosity.

Highest repeatability in handling pastes and emulsions with high viscosity

With our measurement instruments the repeatability remains even under different conditions and situations. It does not matter if you measure syrup from rail or road tankers with occasional air bubbles in the line; or empty a drum of cocoa mass with a pump through a hose.

Level measurement of solids or liquids in any storage container

FMCW radar technology enables reliable and accurate level measurement of liquids and solids even in small or narrow tanks with a dusty atmosphere. A simple and universal level detection for all media is possible regardless of the viscosity of the medium: liquid, paste or solid – whether powder, granular, pellets or sticky mass.

Tailor-made solutions for your processes

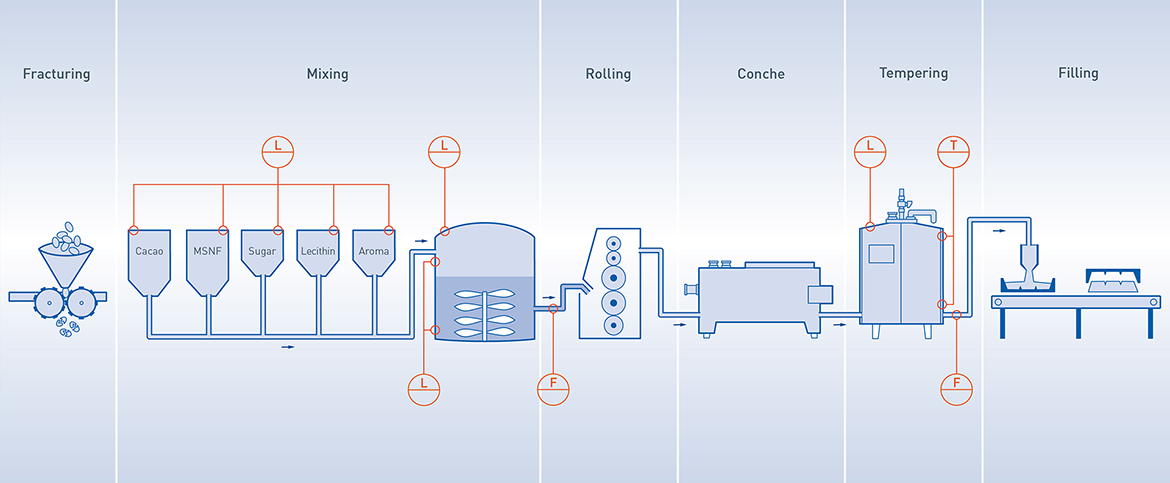

For chocolate production, KROHNE offers suitable devices for level measurement and monitoring, as well as for flow measurement. FMCW radar level gauges for small and large tanks can contactlessly measure and control the amount of cocoa, MSNF, sugar, lecithin and aroma in the silos, as well as the cocoa mass in the mixer. A capacitive point level switch can be used for the min / max signalling in the mixer, regardless of foam, condensate or deposits. The mass flow of the cocoa can be reliably measured by a high-performance Coriolis mass flow meter with a hygienic straight tube. Thanks to EGM™ (Entrained Gas Management) the accuracy of this unit is unaffected by entrained gas content. A heating jacket is available where required.

Our portfolio for the food & beverage industry contains products for flow, level, pressure and temperature measurement as well as inline analysis for hygienic and auxiliary applications. The hygienic instruments feature conformity to EC 1935/2004 and FDA, and are EHEDG and 3A approved. We offer flowmeters for low conductivity liquids and liquids with gas entrainment, mass and volume flowmeters for filling machines, and non-contact level transmitters for liquids and solids – even in dusty atmospheres, operating without a need for air purge. A wide range of hygienic connections are available for all instruments.

Our product portfolio for the Food & Beverage industry

Flow measurement

Flowmeters, flow controllers and flow accessories

Level measurement

Transmitters, switches, indicators and accessories for level measurement

Pressure measurement

Process instruments for pressure and differential pressure applications

Temperature measurement

Assemblies, sensors, transmitters and accessories for temperature measurement

Process analytics

Sensors, assemblies, transmitters, systems and accessories for process analysis

Further information

KROHNE Food & beverage

Learn more about our Global Industry Division and our Products, Services and Solutions for the Food & Beverage Industry

Case Studies

Take a look at our application library, which is full of success stories about process instrumentation in the Food & Beverage industry

Free Webinar

In this webinar, we use the production of chocolate, ice cream and other sweets and cocoa products as an example to illustrate the benefits of the latest technological developments in process measurement.