Guidance and automation of analyser validation

CalSys Analyser Management software

Solution for analyser management and data acquisition

Unlock Operational Excellence with CalSys Analyser Management Software

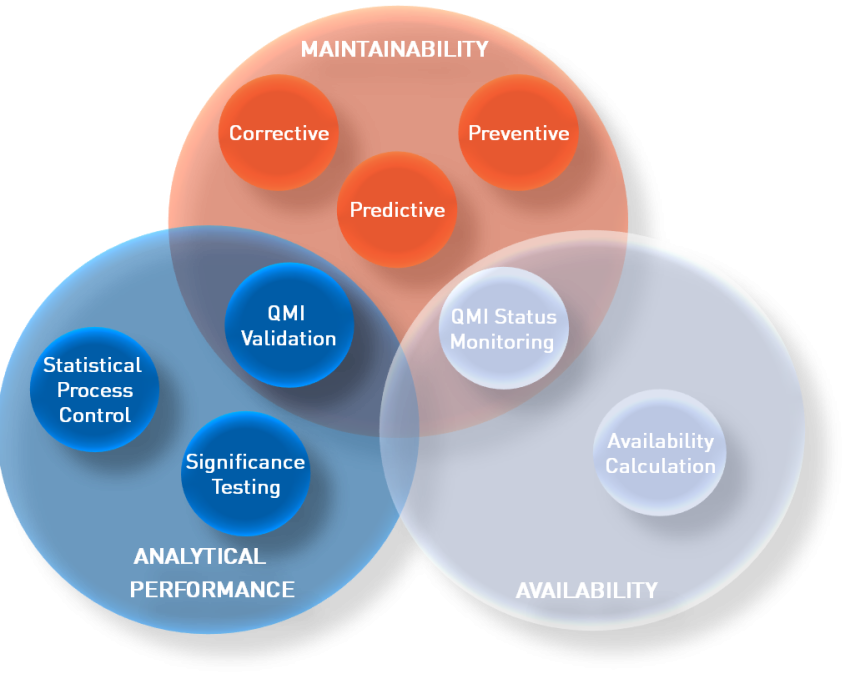

CalSys is an analyser management and data acquisition system (AMADAS) using control charting techniques and statistical process control to determine the analytical performance, availability and maintainability of a broad variety of process analysers and other critical instruments. With its customisable features, integration capabilities, versatile accessibility, streamlined maintenance processes, availability summaries, statistical process control capabilities, enhanced validation options, user management functionalities, and efficient reference bottle management, CalSys enables organisations to achieve operational excellence. Thus, CalSys supports operators in achieving optimal efficiency in the maintenance of gas chromatographs, process analysers, gas detectors, CEMS, laboratory analysers and similar equipment, as well as optimising resources, improving decision-making, and driving productivity in industry-specific analytical processes.

Benefits

Key Features & Functions

Monitor, analyse and improve the performance of quality measurement instruments.

- Data Insights: CalSys provides deep insights into analytical performance, availability, and maintainability, enabling informed decision-making, with real-time monitoring and robust security to ensure data integrity.

- Efficient Workflow: Streamlined communication between instruments, users, and procedures enhances efficiency and resource utilisation, offering guidance and automation for analyser validation.

- Real-time Monitoring: CalSys offers prompt alerts for anomalies, minimising disruptions, and improving analyser uptime while delivering diagnostics on performance.

- Maintenance and Reporting: Predict and detect abnormal behaviour, schedule maintenance and validation, and produce key performance indicators (KPI) for availability figures.

- Content Management: CalSys includes a content management system for hosting manuals and procedures, supporting comprehensive reporting of analytical performance, availability, and maintainability.

Functional Decomposition & Reporting

ANALYTICAL PERFORMANCE REPORTING

- Single validation

- Control chart

- Historical overview

- Significance test

- Reproducibility and Standard Deviation

- Overall Performance Summary

- Overall Analytical Performance

AVAILABILITY REPORTING

- Time related performance indicators

- Overall Availability Performance

MAINTAINABILITY REPORTING

- Instrument datasheet

- Instrument based schedule

- User-based schedule

- Overall maintenance

- Reference bottle overview

- Maintenance action overview

Scalability

CalSys is scalable to meet the customers need:

Manual

- Engineer is guided

- step by step

- Manual entry of data

Semi-automatic

- Engineer is guided

- step by step

- Data is gathered automatically

Automatic

- Entire procedure is automated (including data gathering)

- Can be scheduled automatically

- No human intervention required

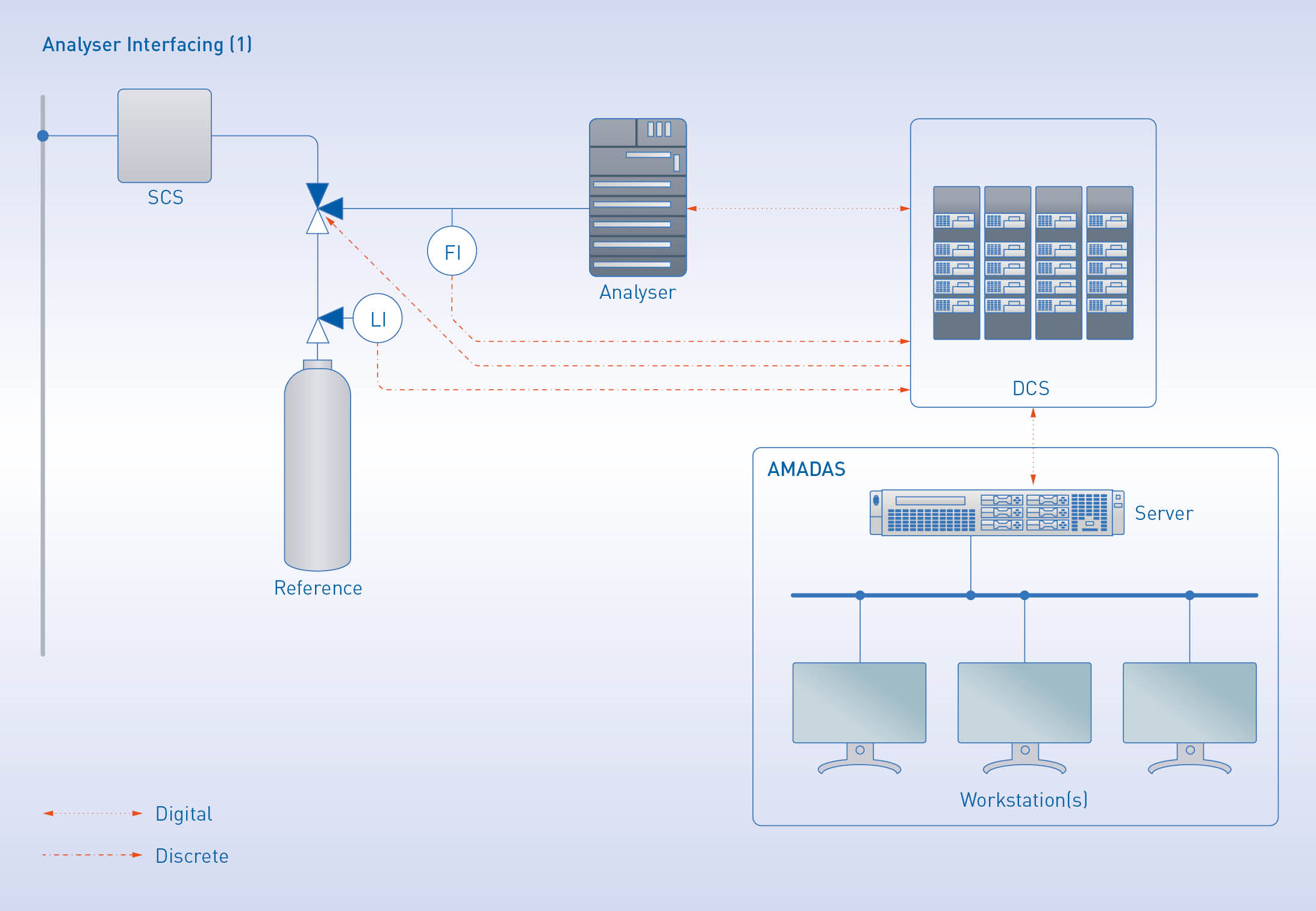

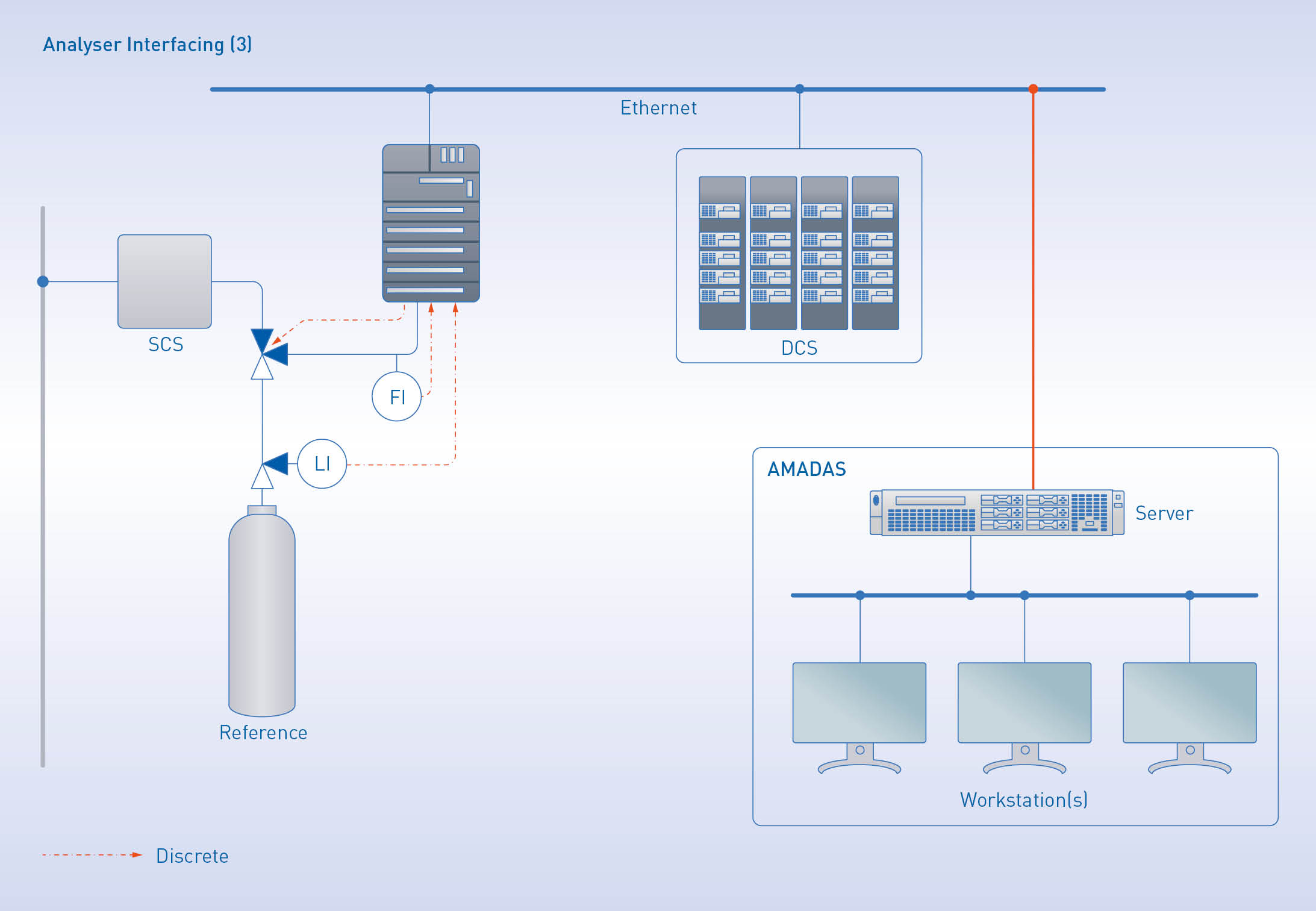

System Architecture

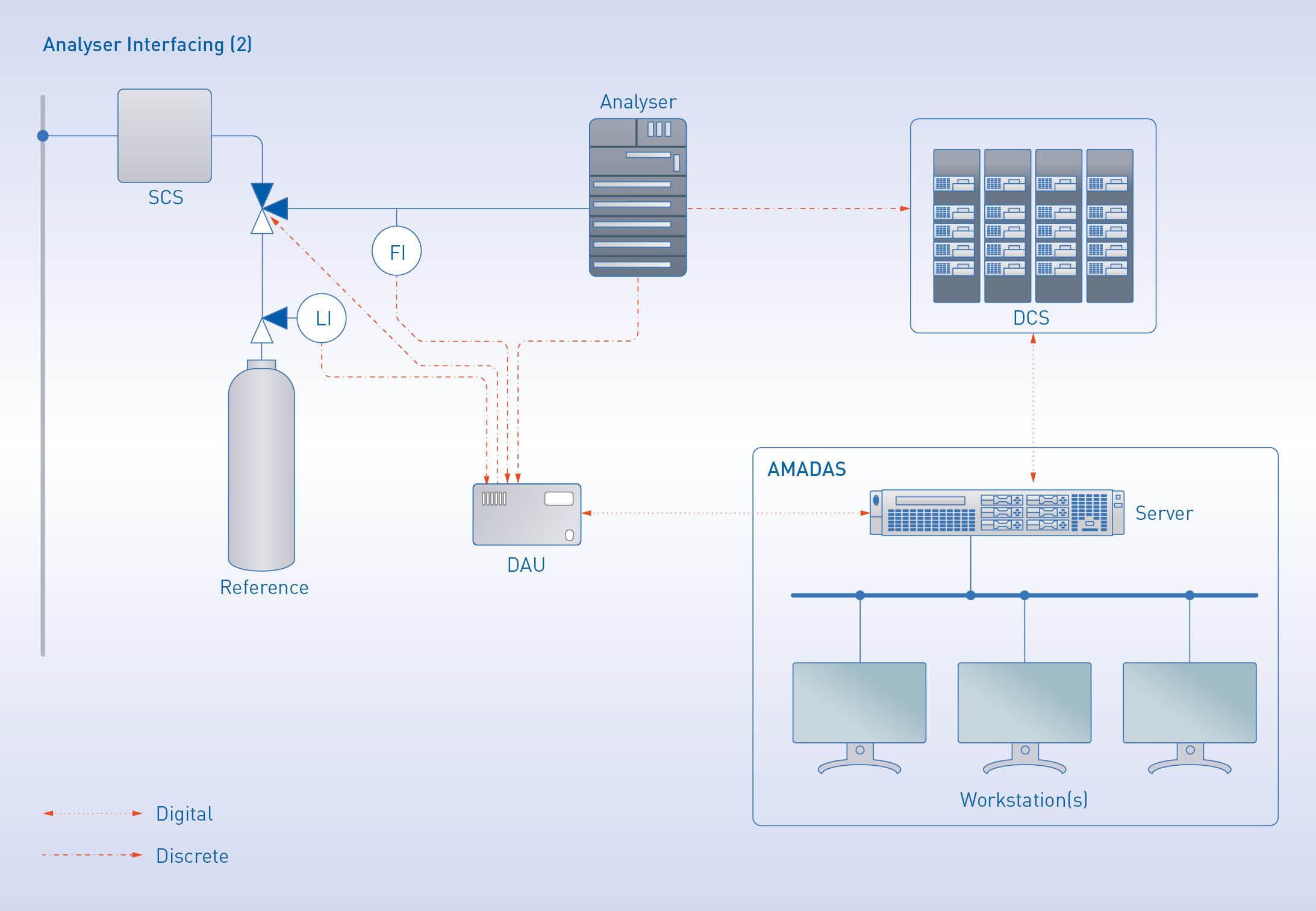

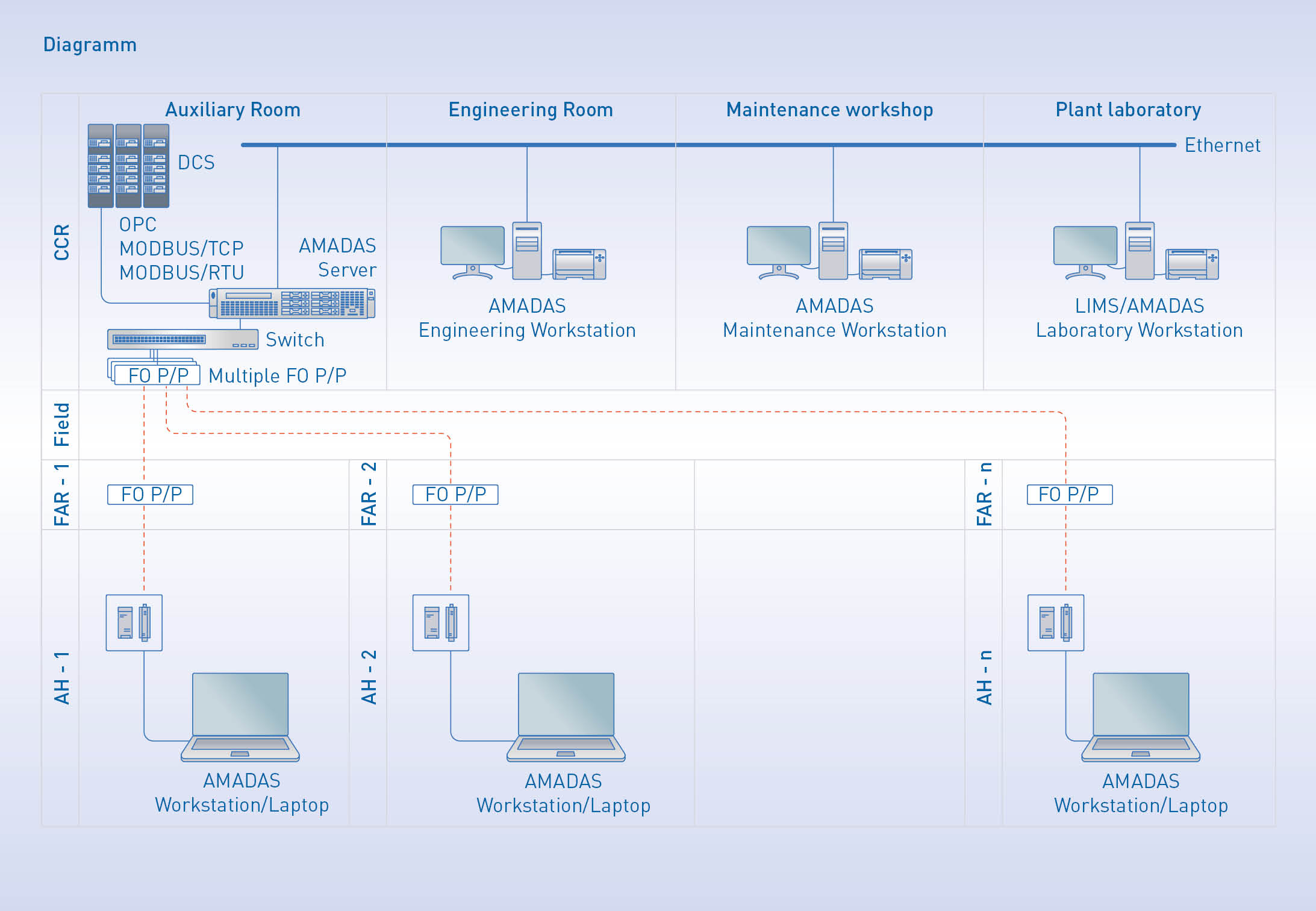

CalSys is a flexible solution that adapts to your needs and operation. So you can choose how you want your Analyser Interfacing to be set up.

AMADAS accesses Analysers thru DCS

AMADAS accesses Analysers directly and thru DCS

AMADAS accesses remotely via network

Diagram

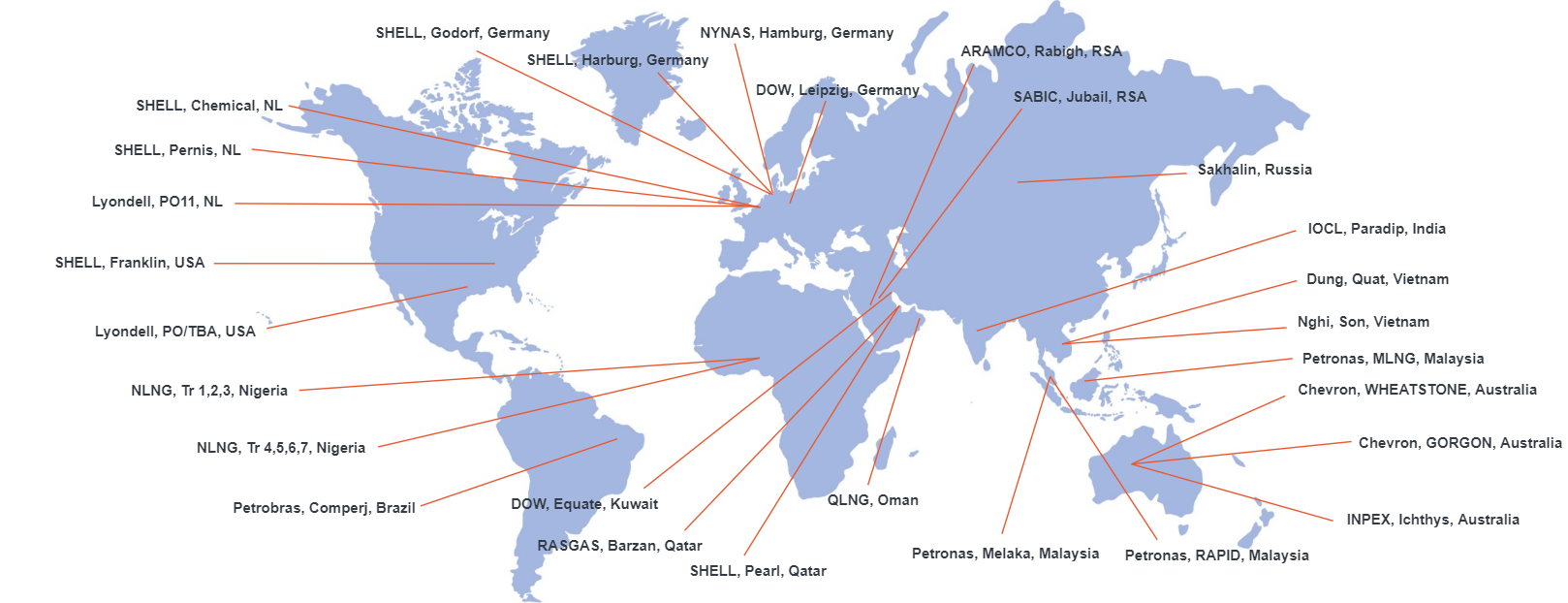

Engineered solutions for process control and automation

KROHNE Solutions provides engineered turn-key solutions for process control and automation – worldwide. Our portfolio ranges from single flow computers to complete skids, and from instrument management software to metering and full monitoring solutions. Our full 360-degree service concept guarantees smooth and continuous operation in the field. From first consultancy to commissioning, we take over the responsibility for the whole project-lifecycle.

Our specialists are dedicated to guaranteeing benefits across the entire value chain of our customers. KROHNE supplies solutions that improve sustainability and efficiency in various segments, even covering demanding applications in the field of renewable energies like hydrogen and carbon capture, and traditional industries such as chemical, oil & gas, power generation, marine and water & wastewater.

Application

Worldwide application experience and support

Real-time product release of LNG

Application Note | Oil & Gas

- Quality release certificate and bill of lading available directly after LNG loading

- Avoiding disputes due to AMADAS automated instrument validation

- ISO 8943, GPA 2172, ASTM 4784 and GIIGNL calculation certified by NMi

Our portfolio of related solutions to complement your application

KROHNE is your reliable partner for process instrumentation and automation. As our client, you benefit from our ability to solve your applications with matching measurement solutions; we offer a complete product portfolio, industry specific system solutions and complementary services for instrumentation projects.

Custody transfer metering systems for crude oil and refined products

Metering solution for liquids

- Straight tube Coriolis and ultrasonic flowmeters to minimise pressure drop

- Systems with mobile or integrated master meters, uni- & bi-directional ball provers or small volume provers

- Comprising flow metering skid, flow balancing, metering control cabinets, sampling and analyser systems, including all supervisory and validation software

Custody transfer metering systems for gases

Metering solution for gases

- Possibility for two ultrasonic flowmeters with different path configurations mounted flange-to flange to avoid common mode errors

- SUMMIT flow computer and SynEnergy supervisory software for gas measurement.

- Comprising flow metering skid, metering control cabinets, sampling and analyser systems, and all supervisory and validation software

Custody transfer metering systems for LNG

Metering solution for liquefied natural gas

- Based on ultrasonic or Coriolis cryogenic flow meters

- From large scale ship (un)loading to bunkering and truck loading

- Comprising flow metering skid, metering control cabinets, sampling and analyser systems, and all supervisory and validation software

Supervisory control cabinets

Complete solution for process control

- Provides control of the metering system, including validation of field instrumentation

- Installed in a safe area, typically in a control room or dedicated building

- Supplied in combination with new metering systems, or for an upgrade to existing systems

Modular flow control and data transfer cabinets

Basic flow control solution

- Cost effective, modular metering control solution

- Based on the SUMMIT 8800 flow computer

- Installed in a safe area, typically in a control room

Metering houses and shelters

Turnkey housing solution for the installation of electronic systems and cabinets on-site

- A safe area for the installation of electronic equipment and cabinets

- Integrated HVAC system where required

- Local operator supervisory work station can be included

Sampling systems

Automatic sampling solution for liquid hydrocarbons

- Sampling systems for stand-alone use, or integrated into the flow metering systems

- In-house design, manufacturing, commissioning and testing

- Fully assembled and tested prior to shipping

- Engineered solution to meet any special project specifications

Analyser houses and shelters

Analyser solution for crude oil, refined products and natural gas

- Quality measurements of crude oil, refined products and natural gas

- Supplied with new metering systems, or as a stand-alone upgrade to existing systems

- Engineered solutions based on customer preferred brands