… retrofits virtually every electromagnetic flowmeter

IFC 300 converter retrofits virtually every obsolete magmeter with new electronics.

Gradually, more and more electromagnetic flowmeters are being discontinued and spare parts and support are no longer available. For you, this could mean: the malfunction of the electronics causes unwanted downtime, which results in significant consequences for your process and plant safety.

IFC 300 not only safeguards your business and assets, it also makes your installation fit for the future, for example with additional features and the latest communication protocols.

Check out the possibilities for upgrading your flowmeters with our service team and …

Make an appointment for a free and no-obligation check:

Worried about process safety and expensive meter updates?

IFC 300 prevents process shutdowns and high investments for new flowmeters!

When making your product decisions, cost and performance must always be balanced. Not with the IFC 300! Because with it, you get more performance for lower costs. There is no need to buy an expensive new flow sensor and the process can continue to run without time-consuming interruptions.

With its unrivalled measurement performance, the comprehensive diagnostics package and its numerous communication options, it ensures a high level of process reliability and is a real gain for your process.

IFC 300 Field, Stainless Steel and Wall versions

Possible reasons for the retrofit:

- Full or partial defect of converter electronics

- Need of communication protocols

- Need of additional outputs

Worried about extensive meter exchanges?

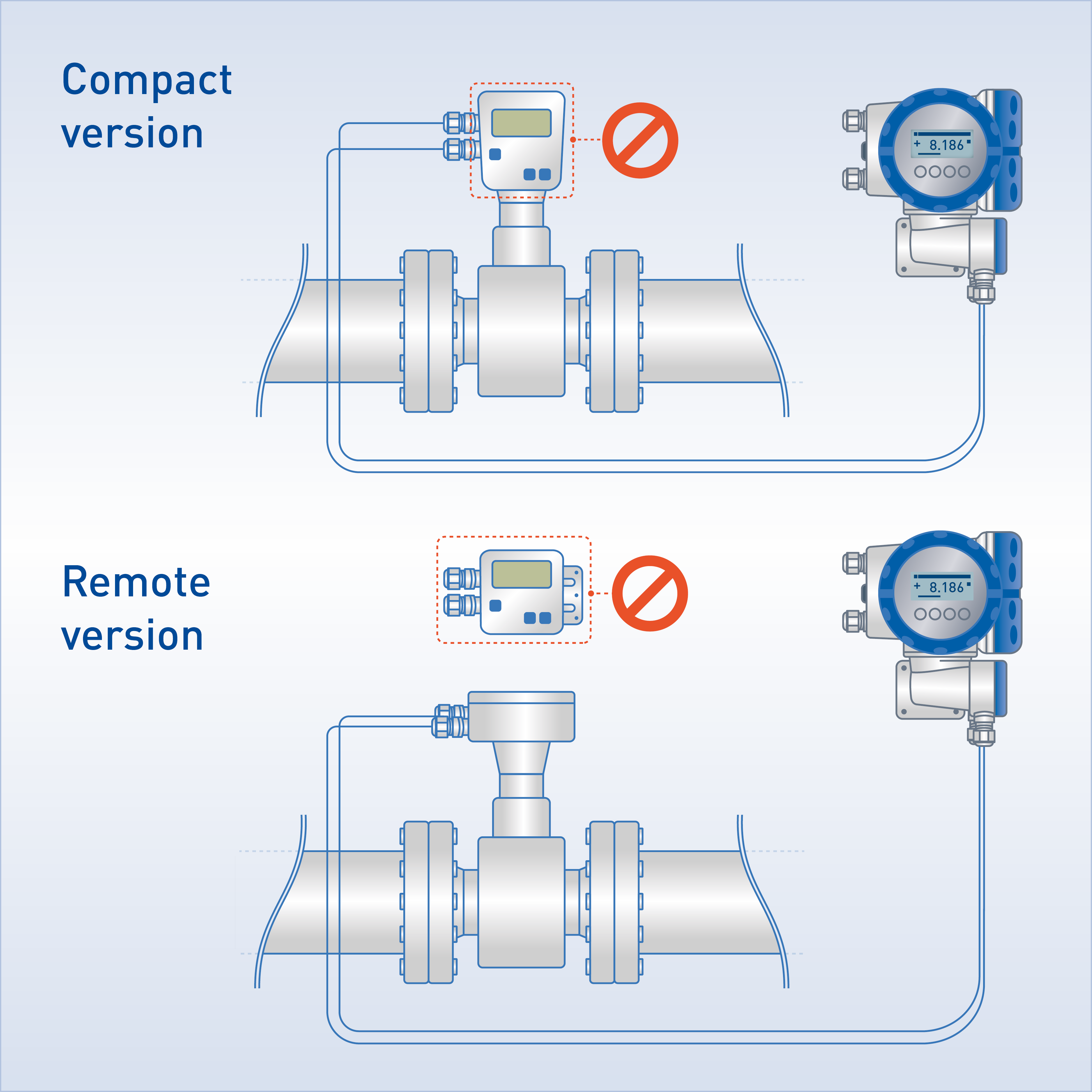

IFC 300 retrofits your old flowmeter quickly and easily!

With the IFC 300, you are opting for a quick changeover to a converter that will accompany you for many years to come – always with the option of upgrading to other communication protocols at short notice and without complications.

KROHNE will check the compatibility of the used sensor and the installation situation in advance.

You have to install the converter and assure that a reference flow is available during start-up for our replacement converter to be adjusted.

Our KROHNE service engineers will support you in commissioning and start up* of the new converter.

* after mechanical and electrical installation

Worried about upcoming communication problems?

IFC 300 makes your flowmeter fit for the future with latest communication protocols!

Over time, you will want to change the communication interfaces. But what should you do if you can’t convert the existing transmitter?

IFC 300 leaves nothing to be desired in terms of communication interfaces. The HART® interface is, of course, standard. But the converter can be individually tailored to meet your needs, which means you will always get the ideal device for your specific process.

IFC 300 communication options:

Worried about insufficient safety-relevant data?

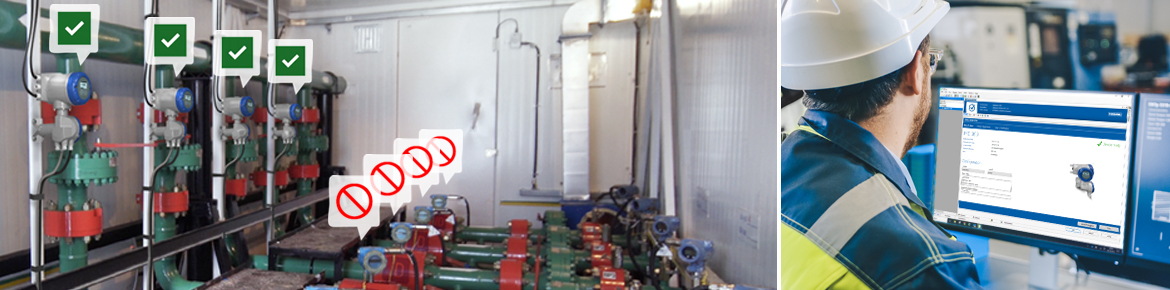

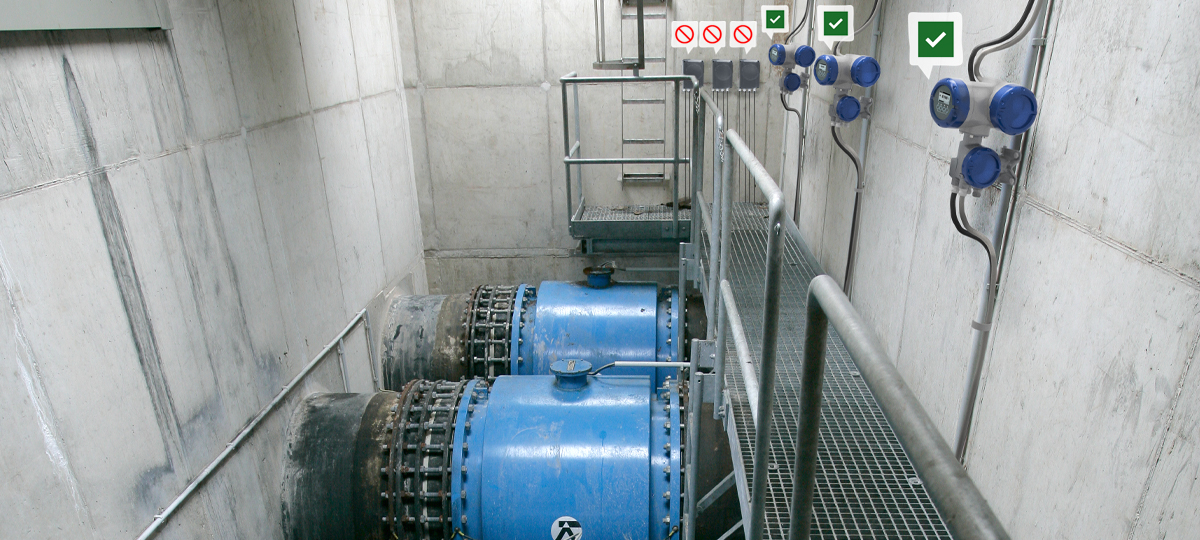

IFC 300 safeguards your process with a comprehensive diagnostics package!

Particularly in the area of process safety, it is important to always be on the ball and to obtain corresponding data from the process that can be used to minimise risks. If this is not possible with the current transmitter, switching to the IFC 300 is the right decision.

Reliable diagnostics of:

- Detection of gas bubbles or solids

- Changing or too-low conductivity (e.g. during change of media or empty pipe)*

- Deposits or coating on the electrodes

- Electrode corrosion

- Too-high media or ambient temperature*

* depending on the old sensor

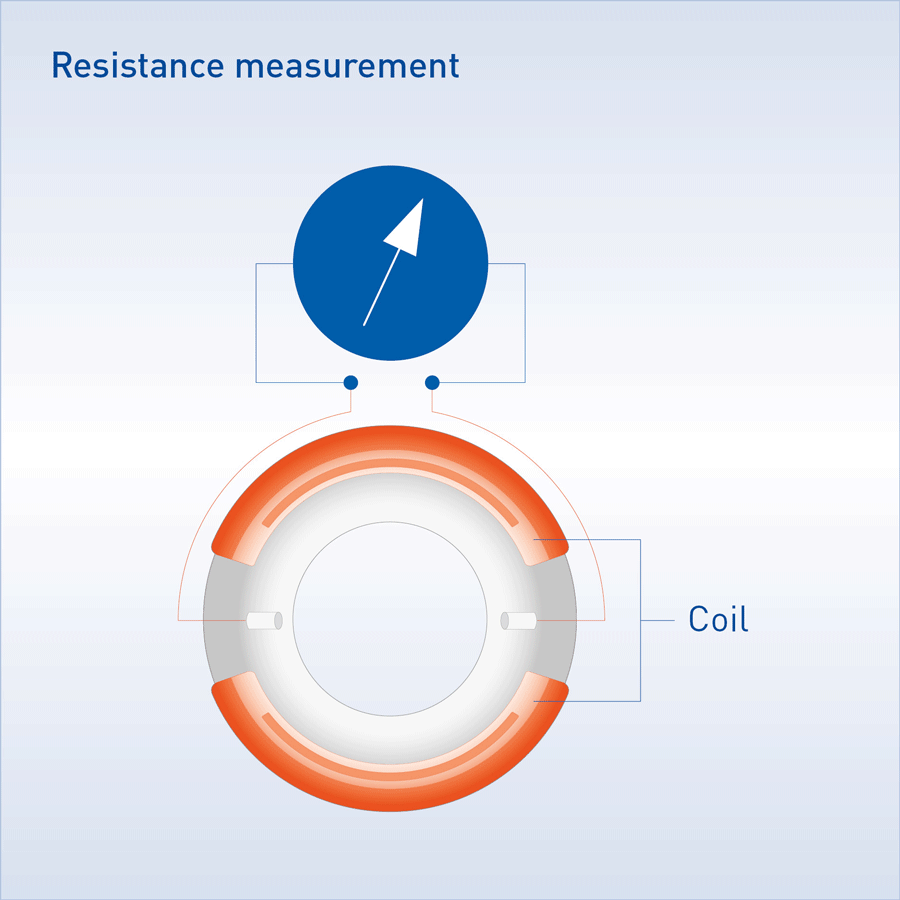

Resistance measurement for detecting electrode covering, electrode short-circuit, excessively low conductivity and for measuring the conductivity and the coil temperature (media temperature).

For the noise measurement the electrode signal is multiplied with a test signal, without noise the resulting voltage is zero.

Further information

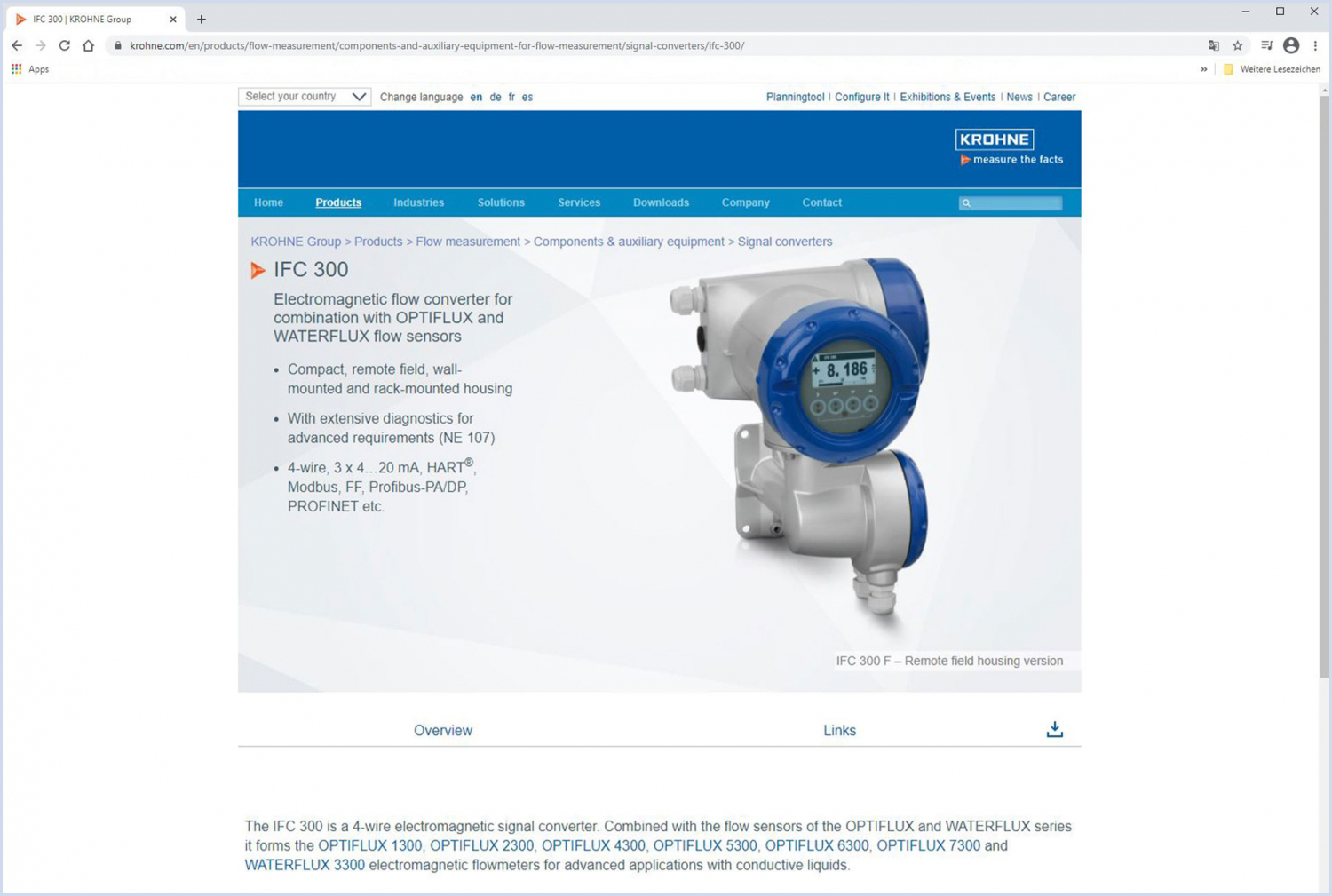

IFC 300 product page

Get a quick overview of the converter, technical highlights, documentation and product variants

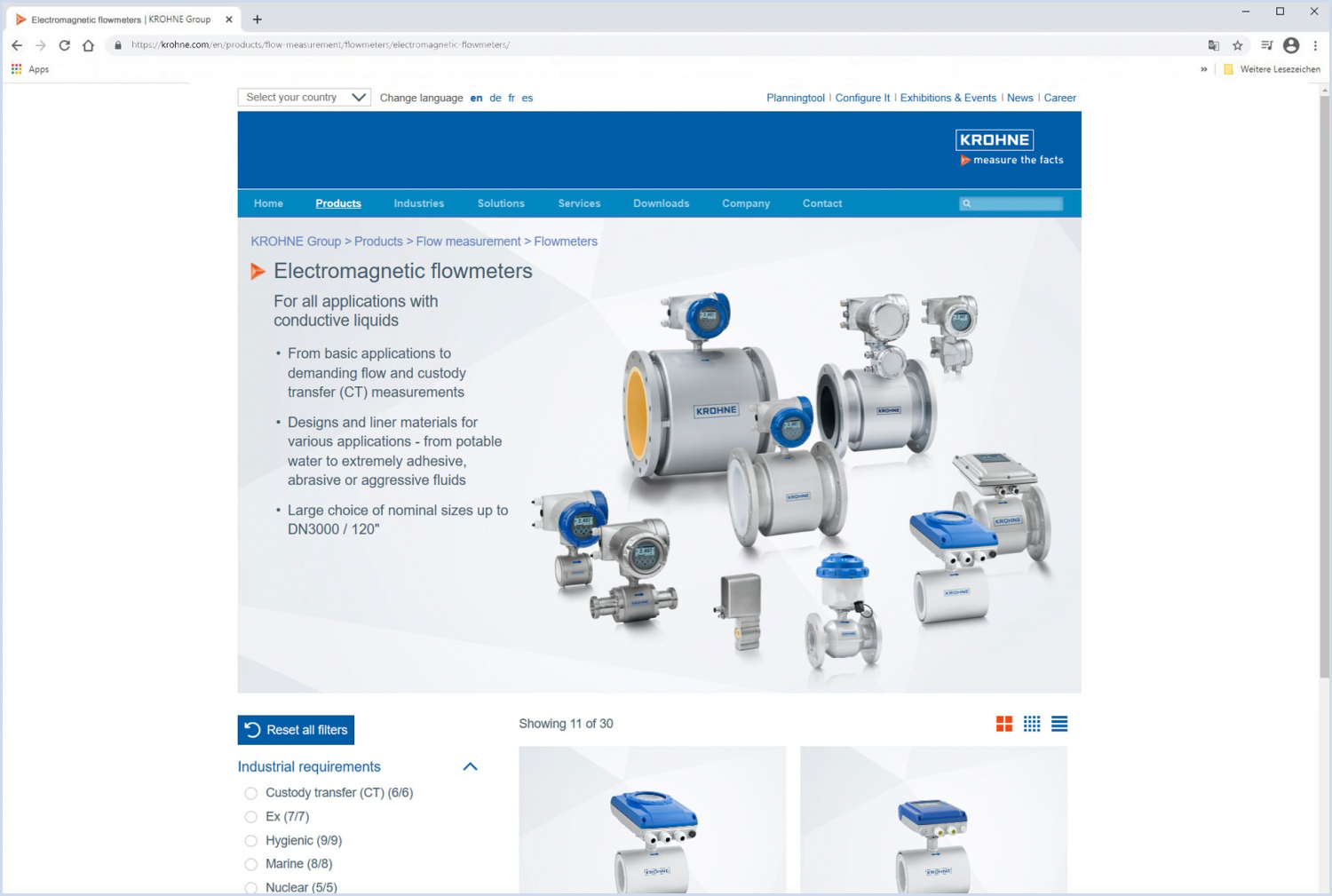

Electromagnetic flowmeters product page

Get a quick overview of all electromagnetic flowmeters, technical highlights, target applications and product variants

Free eLearning course electromagnetic flowmeters

The course covers the measuring principle and the functioning as well as general properties and applications

Check out the possibilities for upgrading your flowmeters with our service team!

Make an appointment for a free and no-obligation check:

KROHNE Messtechnik GmbH

Ludwig-Krohne-Str. 5

47058 Duisburg

Germany

www.krohne.com