Change production from a batch to an inline blending principle

Accurate and reliable measurement solutions for Pet Food production

Increase efficiency in your existing process

An efficient production often means a challenging production process. Manufacturers of pet food products have special requirements for their variety in form and shape. Their main ingredients in the production facility can be grains, frozen blocks of meat and liquids. The KROHNE Global Industry Division Food & Beverage accepts these challenges and offers individual measurement solutions.

In the pet food manufacturing process, achieving a high level of safety with the best possible efficiency is the priority: this sets highly challenging demands on the measurement technologies used. Please accept our invitation to meet in person, or online, to discuss your process improvement potential. Let us help to enable the evolution of your manufacturing process with our dedicated industry and application know-how and high-quality products.

Specialists from our dedicated Food & Beverage division are at your disposal to meet your process challenges, worldwide. Being an instrumentation supplier for the Food & Beverage industry for over 20 years, we have gained industry- and application-specific know-how that we have incorporated into our devices and solutions.

Unlock improvements to give faster production and tighter control of core and costly ingredients

Handling of base ingredients

Measuring your process

Filling/dosing your final product

One of the biggest challenges in the manufacture of prepared pet food is to increase efficiency and to lower costs without compromising the overall efficiency of production. KROHNE offers flow, pressure, level and temperature measurement devices for standard liquids, as well as analytical instruments for quality control. In addition there is now a possibility to measure ground meat, meat slurry streams and the blend of frozen meat with fresh ground meat behind the cutter as if it were a simple liquid.

Allow us to challenge the use of scales or load cells, where these may be subject to be replaced by inline flow and simultaneous density measurement with OPTIMASS Coriolis flowmeters.

Enabling measurement technology for pet food production

Your production processes are equally unique as your products on the market. KROHNE measurement technology offer a disrupting way and method to drastically increase the efficiency of how you produce your finished pet food or feed products. Several special features help optimise your production:

High accuracy flow measurement of slurries and the final product

Our Coriolis flowmeters with EGM™ entrained gas management maintain operation and high repeatability of measurements – despite the presence of fibres, solids or air entrainment in the slurry or any other kind of mash. Mass flow and direct density measurement of aerated products is already possible in the mixed stage.

Continuous level measurement in small and narrow tanks with agitators

Our hygienic radar level devices ensure reliable measurement independent of process conditions like temperature, pressure, density, viscosity or mixed gases and steam. It is particularly suitable for applications in small tanks with internal obstructions like agitators. This continuous measurement enables an automated process that keeps stock levels constantly replenished and maximises product output.

Point level detection of tough, pasty or highly adhesive media

Our capacitance level switches for advanced hygienic applications detect low or high level, so are often used as either dry-run or overfill protection. These devices are able to detect foam or even a change in media characteristics. They are easy to clean and the risk of clogging with product is minimised.

Change production from a batch type to an inline blending principle

Our devices weigh meat slurry streams inline and in real time. This method eliminates process delays and interrupts and unlocks the potential to accelerate the production scale. In addition, unwanted production tolerances can be tightened and the highest repeatability will be enabled, even under challenging conditions.

Tailor-made solutions for your processes

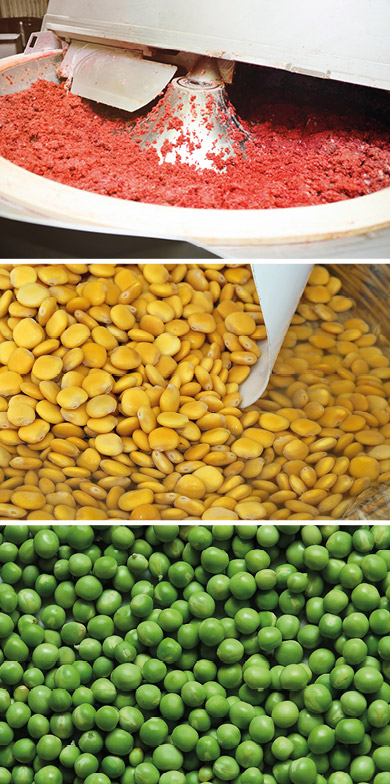

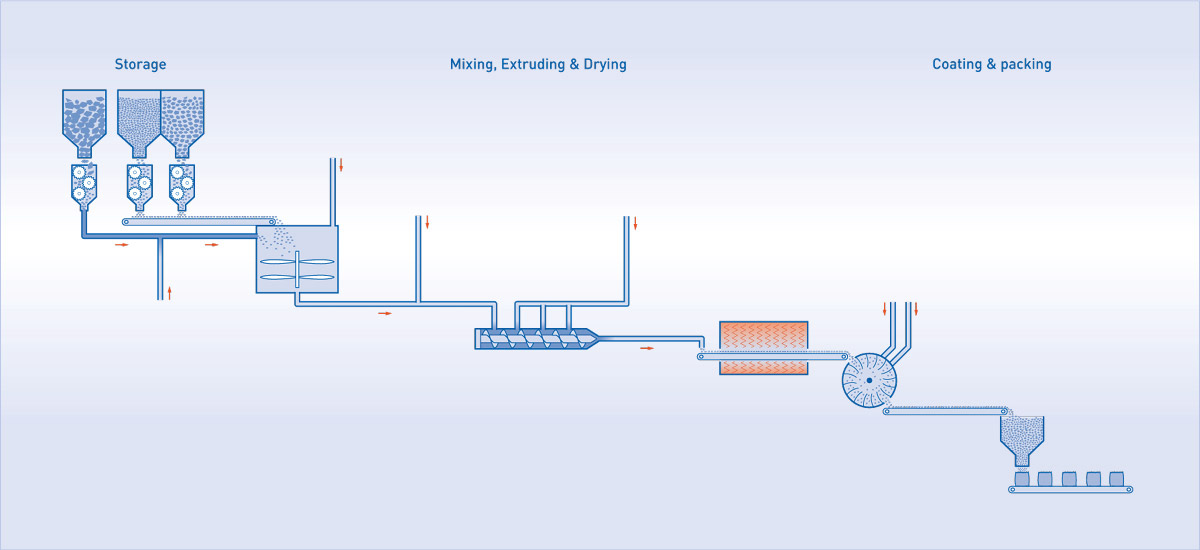

The primary ingredients in pet food are meat, poultry, seafood, feed grains, and soybean meal. Liquid ingredients may include water, meat broth or blood. Salt, preservatives, stabilizers, and gelling agents are often necessary. Gelling agents allow greater homogeneity during processing and also control the moisture. Ingredients vary depending on the type and style of pet food and the manufacturer. The basic difference between canned and dry pet foods is the amount of moisture. Canned food contains between 70 and 80% moisture, since these are generally made from fresh meat products, while dry pet food contains no more than 10%. After storage and grinding of the ingredients, the further processing includes mixing, extruding and drying. After adding extra coatings, fat, flavouring or vitamins, the final product is filled and packaged.

KROHNE offers precisely tailored measuring devices for these tasks. Fast, robust and extremely accurate temperature sensors, as well as ultra-compact and modularly expandable pressure transmitters for hygienic pressure and level measurement applications are available with a variety of hygienic connections. Coriolis mass flowmeters provide exact results for both simple and demanding hygienic applications. Thanks to the EGM™ technology by KROHNE (Entrained Gas Management), Coriolis devices can even do this with entrained gas proportions in the flowing mixtures of up to 100%. FMCW radar level measuring devices with a large selection of hygienic process connections enable reliable, continuous, non-contact level measurement. Capacitive level switches, which only require a short immersion depth in the process, are not confused by foam, condensate or deposits on the probe. All devices are EHEDG and 3-A certified and meet the requirements of FDA and EC1935 / 2004.

Our product portfolio for the Food & Beverage industry

Flow measurement

Flowmeters, flow controllers and flow accessories

Level measurement

Transmitters, switches, indicators and accessories for level measurement

Pressure measurement

Process instruments for pressure and differential pressure applications

Temperature measurement

Assemblies, sensors, transmitters and accessories for temperature measurement

Process analytics

Sensors, assemblies, transmitters, systems and accessories for process analysis

Further information

KROHNE Food & beverage

Learn more about our Global Industry Division and our Products, Services and Solutions for the Food & Beverage Industry

Case Studies

Take a look at our application library, which is full of success stories about process instrumentation in the Food & Beverage industry