Flow measurement devices for natural gas and LNG, monitoring of high-pressure natural gas injection to produce crude oil

Leading measurement solutions for Liquefied Natural Gas

Maximise your efficiency and process reliability across the entire LNG value chain

The LNG and natural gas industry presents many challenges, one being the process of transportation. To maximise the transport capacity of the volumenous natural gas, it is often cooled down to approximately -162 °C, at which temperature methane condenses to a liquid, with an occupied volume reduced 600 times. So accurate custody transfer flowmeters are key in all loading and unloading operations, also as some LNG vapourises during transport, which is often used as fuel for the ship.

KROHNE has a long track record in cryogenic measurement instrumentation. Back in the early 1990 KROHNE flowmeters were already installed for liquefied gas measurement at the Osaka LNG regasification plant.

Today, KROHNE offers a full portfolio of Coriolis and Ultrasonic flowmeters, Custody Transfer metering systems, metering supervisory and load-out quality release software, i.e. instrumentation and metering solutions for the entire LNG value chain.

- Measurement of natural gas entering to the liquefaction terminal

- Process instrumentation used in the liquefaction process

- High accuracy flow and quality measurement during loading of the LNG shuttle

- Measurement of LNG, natural gas, (sea) water and odorisation in break-bulk and gasification terminals

Specialists from our dedicated Oil & Gas division are at your disposal to meet your process challenges, worldwide. Being an instrumentation supplier for the oil & gas industry for over 20 years, we have gained industry- and application-specific know-how that we have incorporated into our devices and solutions.

Measurement solutions for Liquefied Natural Gas

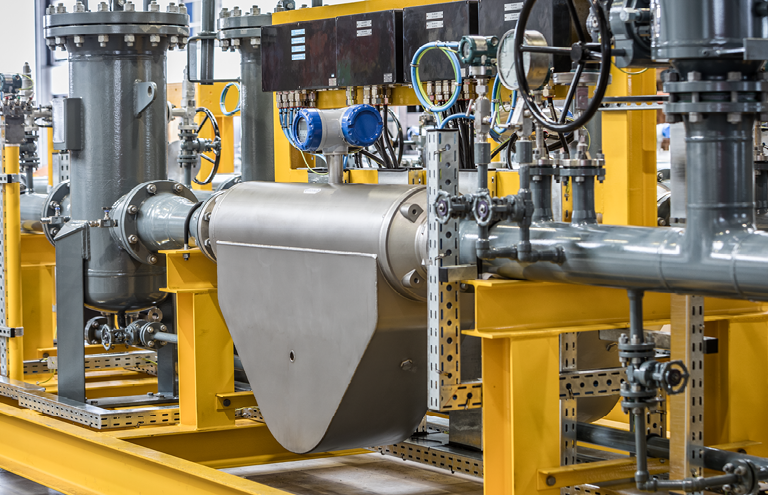

Flow measurement devices for natural gas and LNG

Monitoring of high-pressure natural gas injection to produce crude oil

Notwithstanding pressure and temperature changes, the OPTIMASS 6400 provides long-term stable flow measurement. There is transparency over the amount of natural gas injected and consumed, this allows the operator to optimise the lift process and contribute to undisputed billing procedures with the landowner.

Complete custody transfer metering systems for LNG

From large scale ship (un)loading to bunkering and truck loading

Our Custody Transfer (CT) metering solution measures both the volume and quality of LNG. The in-house development of flowmeters, flow computers and supervisory software guarantees seamless integration of metering and diagnostic features. KROHNE LNG metering systems can be designed as a master-duty configuration, where a Z-cross over allows periodical verification of the duty meters against a master meter. The diagnostic features of the flowmeters are used to guarantee maximum performance and lowest measurement uncertainty of the system.

LNG-Quality Release System (L-QRS)

The software solution for efficient LNG loading operations

KROHNE’s LNG Quality Release System (L-QRS) is a software solution used to minimise the risk of disputes, by automating the volume and quality measurement during (un)loading, so that manual sample handling is no longer required. Also, Bill-of-Lading and Quality Release Certificates are available instantly. Thus, the system avoids costly sample handling, laboratory tests and retrospective corrections of the bill of lading and quality certificates.

The system does NMi certified calculations in an NMi certified flow computer, and is compliant with ISO 8943, GPA 2172, ASTM 4784 and GIIGNL. It combines analyser management and data acquisition (AMADAS) functionality to ensure the best results.

SUMMIT 8800

The flow computer solution for the visualisation of accurate LNG measurements

The SUMMIT 8800 allows a graphical representation of the measurement process, with all measured values shown in real time. Up to 5 different types of meters combined in one flow computer, with CT measurements still being processed within 0.25s. The SUMMIT 8800 communicates via digital, analogue, serial and Ethernet interfaces to obtain the measurement and diagnostics from the field converters and analysers. The automatic Performance Monitoring extends recalibration intervals.

CalSys Analyser Management software

The Analyser Management software for dynamic LNG quality measurement with certified Quality Release Modules

For an effective performance monitoring of quality measurement instruments (QMI) and automated analyser validation as well as statistical process control. Amongst others per ASTM D3764, ASTM D6299 and OP 97-30425.

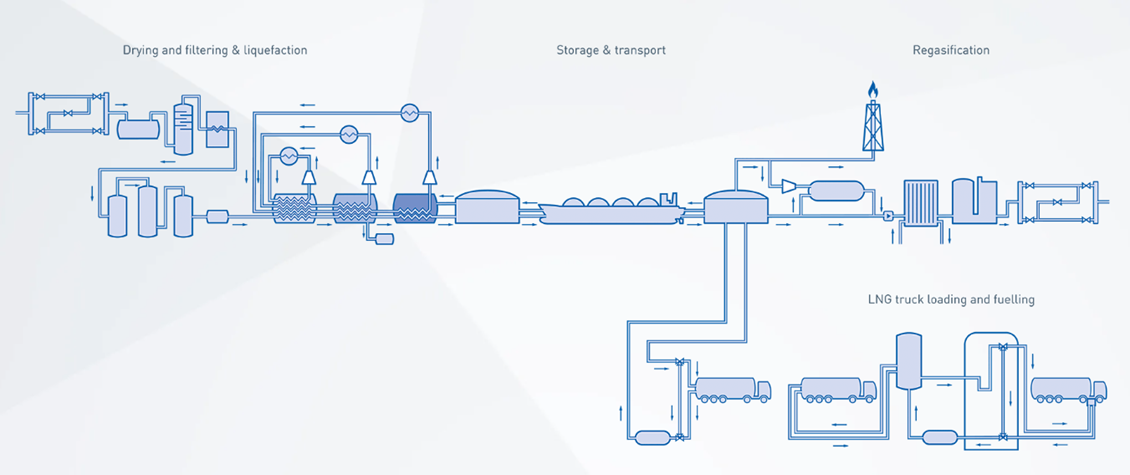

LNG Processes

Quality and composition-based measurement of drying, filtering and liquefaction

After the natural gas entering the liquefaction plant has been measured by a Custody Transfer metering system, the filtering and liquefaction process can start. During that process, KROHNE Ultrasonic OPTISONIC flowmeters are used to measure the natural gas flows and in the same process the coolants used in the cold boxes. KROHNE OPTIWAVE and OPTIFLEX level instrumentation is used to measure the level in separators, scrubbers and tanks. CalSys (AMADAS Analyser Management) software systems guarantee the performance of the analysers used to determine the quality of the natural gas and LNG.

Monitoring of loading and fuelling

KROHNE OPTIMASS Coriolis meters are used in small scale LNG and break bulk projects to measure the amount of LNG that is loaded in a truck or bunker ship. KROHNE also supplies custody transfer approved delivery systems on LNG tanker trucks. These systems include an OPTIMASS Coriolis flowmeter, a SUMMIT 8800 flow computer and a ticket printer, all per local metrology regulations.

Regasification – Converting LNG to natural gas

In receiving terminals KROHNE ultrasonic flowmeters are used to check the delivered amount of LNG and the amount of boil of gas that is being returned to the shuttle during offloading. During regasification, KROHNE flowmeters are used to measure natural gas, with process or custody transfer accuracy, and seawater that is pumped through the heat exchanger.

Storage and shipping – Delivery flow monitoring of cryogenic LNG

For loading and unloading of LNG shuttle tankers, KROHNE flowmeters and Custody Transfer metering systems are used to measure the volume of LNG and Boil-Off gas. KROHNE also provides analyser systems to measure the LNG quality and calorific value. KROHNE L-QRS software is used to fully automatically issue the Bill of Lading and Quality Release Certificate directly after loading or unloading has been completed, without the need for manual sample handling.

Read more and discover the KROHNE products in the specific processes: https://krohne.com/en/industries/oil-gas-industry/liquefied-natural-gas

Product portfolio for LNG

KROHNE is your reliable partner for process instrumentation and automation. As our client, you benefit from our ability to solve your applications with suitable measurement solutions. We offer a complete product portfolio of flow, temperature, pressure and level devices, industry specific system solutions and complementary services.

OPTIMASS 6400

Coriolis mass flowmeter for advanced process applications

- High accuracy (±0.05% flat), for cryogenic to HT media (-200…+400°C / -328…+752°F); maintains operation over a wide range of gas fractions and complex flow conditions (EGMTM)

- SIL 2/3; CT: OIML R117, R137, MI-005, MI-002; API, AGA; hygienic certifications

- Flange: DN10…300 / ½…12″, max. PN 160 / ASME Cl 1500

- 3 x 4…20 mA, HART®7, Modbus, FF, Profibus-PA/DP, PROFINET, EtherNet/IP™, Bluetooth®

OPTISONIC 7300

Ultrasonic flowmeter for natural gas, process gas and utility gas applications

- 2-path meter, for standard volume flow metering, independent of media properties

- No maintenance, no pressure loss, large dynamic range

- Flange: DN50…1000 / 2…40″, max. PN450 / ASME Cl 2500; also weld-in connections

- 3 x 4…20 mA, HART®, Modbus, FF

ALTOSONIC V12

Ultrasonic flowmeter for custody transfer (CT) measurement of gases

- 12-chord meter, for high accuracy flow metering of natural gas

- CT: OIML R137 (class 0.5), MI-002, AGA9 etc.

- Many variants, extensive CBM diagnostics free of charge

- Flange: DN100…1600 / 4…64″; max. PN450 / ASME Cl 2500

OPTISONIC 3400

Ultrasonic flowmeter for liquid process applications

- Accurate 3-path meter: large dynamic range, maintenance-free, no pressure loss

- Cryogenic (-200°C/-328°F) and HT (+250°C/+482°F) versions; viscosities up to over 1000 cSt

- Flange: DN25…3000 / 1…120″, max. PN200 / ASME Cl 1500; also weld-ends

- 3 x 4…20 mA, HART®, Modbus, FF, Profibus-PA/DP

ALTOSONIC 5

Ultrasonic flowmeter for custody transfer (CT) measurement in upstream and midstream applications

- Multipath inline meter for crudes, refined products, cryogenic media and chemicals

- CT: OIML R117, API compliant

- Flange: 4…24″; max. ASME Cl 600

- -200…+250°C / -328…+482°F

BM 26 F2200

Magnetic bypass level indicator with guided radar (TDR) for liquid level applications

- Continuous, redundant measurement using two measurement principles in one device

- Measuring range: 0.3…5.5 / 1…18 ft (longer on request)

- Density: 0.5…3 kg/l / 31…187 lb/ft3

- -50…+300°C / -58…+570°F; -1…100 barg/ -14.5…1450 psig

OPTISWITCH 5300

Vibration level switch for heavy-duty applications

- Point level detection of liquids under extreme conditions

- Probe length: up to 3000 mm / 118 ft

- ≥0.47 g/cm3/ 0.017 lb/in3(optional: ≥0.42 g/cm3 or 0.015 lb/in3)

- -196…+450°C / -321…+842°F; -1…160 barg/ -14.5…2321 psig

SUMMIT 8800

Flow computer for custody transfer (CT) measurement

- Cost effective solution due to modular hard- and software design

- Full colour graphical touch screen for maximum process transparency

- Easy operator access enabling time efficient maintenance

- Automatic Performance Monitoring extends recalibration interval

Complete measurement solutions for LNG

Custody transfer metering systems

Metering solution for LNG

- Based on ultrasonic, Coriolis, turbine or PD flowmeters

- Covering the initial design phase through to on-site commissioning and training

- Comprising flow metering skid, flow control, metering control cabinets, sampling and analyser systems, including all supervisory and validation software

LNG-Quality Release System (L-QRS)

Software solution for efficient LNG loading operations

- Instant availability of both certificate of quality & bill of lading, based on real-time quality measurement

- Certified by NMi and compliant with ISO 8943, GPA 2172, ASTM 4784, GIIGNL

- Automated instrument validation and statistical process control according to international standards

- Energy calculations, loading mass balance and billing reports on vapour returns

CalSys Analyser Management software

Solution for analyser management and data acquisition (AMADAS)

- Effective performance monitoring of quality measurement instruments (QMI)

- Automated analyser validation and statistical process control

- Complies with international standards and methods (ASTM D3764, ASTM D6299, OP 97-30425 etc.)

- Increased availability of gas chromatographs and critical process analysers

SynEnergy Supervisory and visualisation software

Solution for continuous process monitoring and reporting

- HMI/SCADA software for measurement solutions

- State of the art HTML5 secure web technology

- Optimisation of operation results due to predictive maintenance

- Easy integration into existing DCS and ERP networks

PipePatrol Pipeline Management

Smart monitoring and protection of pipelines

- Comprehensive suite of modules for leak, theft and line break detection, plus monitoring of tightness and lifetime stress

- Complete and sensitive protection of oil, gas, water and multiproduct pipelines

- From single software applications to full packages including instrumentation

Supervisory Control Cabinets

Complete solution for process control

- Provides control of the metering system, including validation of field instrumentation

- Installed in a safe area, typically in a control room or dedicated building

- Supplied in combination with new metering systems, or for an upgrade to existing systems

Analyser houses and shelters

Analyser solution for natural gas

- Typical analysers for natural gas include gas chromatographs, water- and hydrocarbon dew point, sulfur, mercury, base density, line density and trace oxygen analysers

- Fully wired, pre-configured and tested before installation on site

- Can be supplied as part of a complete metering system, or as stand-alone analyser modules

Applications

Real-time product release of LNG

Application Note | Oil & Gas

- Quality release certificate and bill of lading available directly after LNG loading

- Avoiding disputes due to AMADAS automated instrument validation

- ISO 8943, GPA 2172, ASTM 4784 and GIIGNL calculation certified by NMi

Custody transfer flow measurement for (un)loading of LNG

Application Report | Oil & Gas

- Equipping a dispensing system for cryogenic fuels with a Coriolis mass flowmeter

- Continuous measurement and indication of 2-phase-flow in the event of boil-off-gas (BOG)

- Improved control of loading procedure, cooling time and product quality

Custody transfer LNG ship loading and unloading

Application Report | Oil & Gas

- High accuracy Coriolis mass flow measurement of LNG with a large flowrate

- Complete custody transfer (CT) measuring system for cryogenic liquids

- Continuous and consistent measurement results from start to finish even in the event of entrained BOG (Boil-off Gas)

Flow volume control of natural gas storage

Application Report | Oil & Gas

- Optimisation of gas transport from onshore to offshore platform

- Maintenance free measurement solution with excellent long term stability

- Accurate alternative to mechanical gas flow meters

Ultrasonic flow measurement for the internal monitoring of natural gas quantities

Application Report | Oil & Gas

- Flow measurement of natural gas at a storage facility

- Increased requirements for measuring accuracy

- Improved management of internal gas measurements

Custody transfer (CT) flow measurement for a natural gas fuel system

Application Note | Power Generation

- Flow metering solution for gas supply to load-flexible combined cycle gas turbine (CCGT) units

- Equipping fuel skids with calibrated metering sections and flow computers

- Maintenance-free operation and long-term stable, repeatable flow measurement using ultrasonic gas

Contact us

Specialists from our dedicated Oil & Gas division are at your disposal to meet your process challenges, worldwide. Being an instrumentation supplier for the oil & gas industry for over 20 years, we have gained industry- and application-specific know-how that we have incorporated into our devices and solutions.