Instant availability of bill of lading and quality certificates avoids costly retrospective corrections once the vessel has departed

LNG-Quality Release System (L-QRS)

Software solution for efficient LNG loading operations

Loading or unloading of LNG requires a quality certificate and a Bill of Lading as a minimum according to GSPA (Gas Sales Purchase Agreement), to determine the amount of energy transferred. The information for these documents is currently derived from multiple instruments and independent operational systems. Conventionally, all this data is manually collected and processed in mostly Excel based worksheets, without traceable references to instrument uncertainties, standards and with no dynamic validation.

L-QRS from KROHNE takes you to a new level of LNG loading operational management, using on-line measurements and certified statistical calculations, including quality and outlier calculations. The L-QRS system not only facilitates and automates the process, but also saves on your maintenance costs and increases availability, resulting in less product give-away.

Specialists from our dedicated Oil & Gas division are at your disposal to meet your process challenges, worldwide. Being an instrumentation supplier for the oil and gas industry for over 20 years, KROHNE have gained industry- and application-specific know-how that we have incorporated into our devices and solutions.

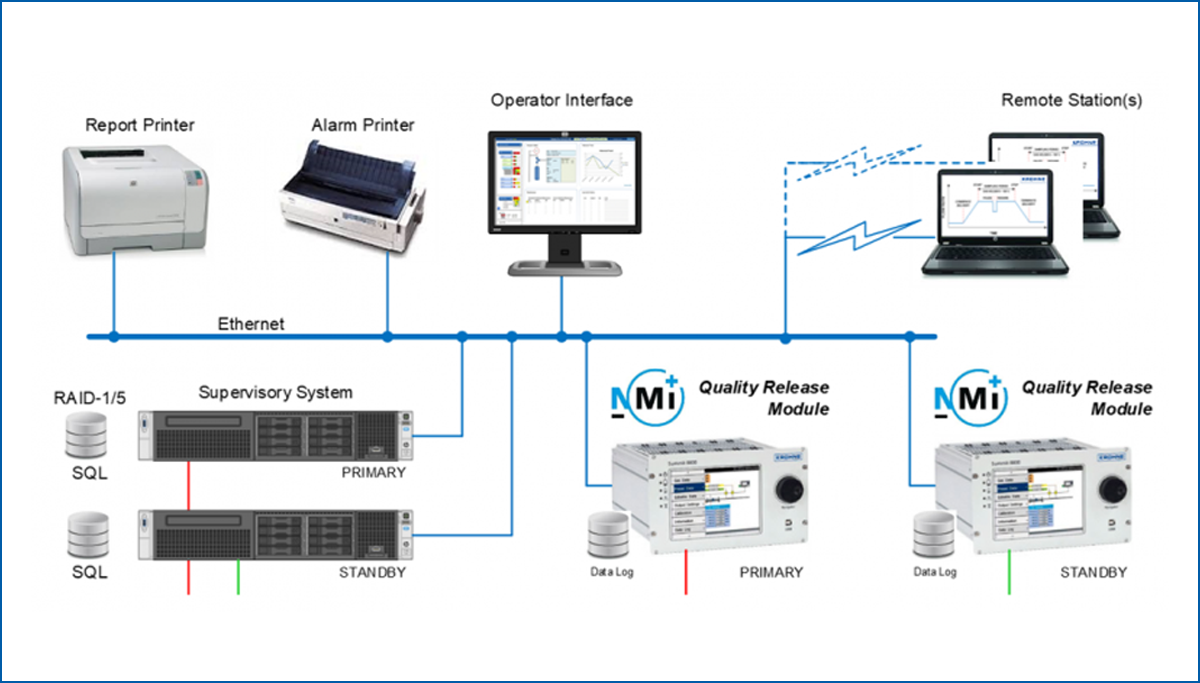

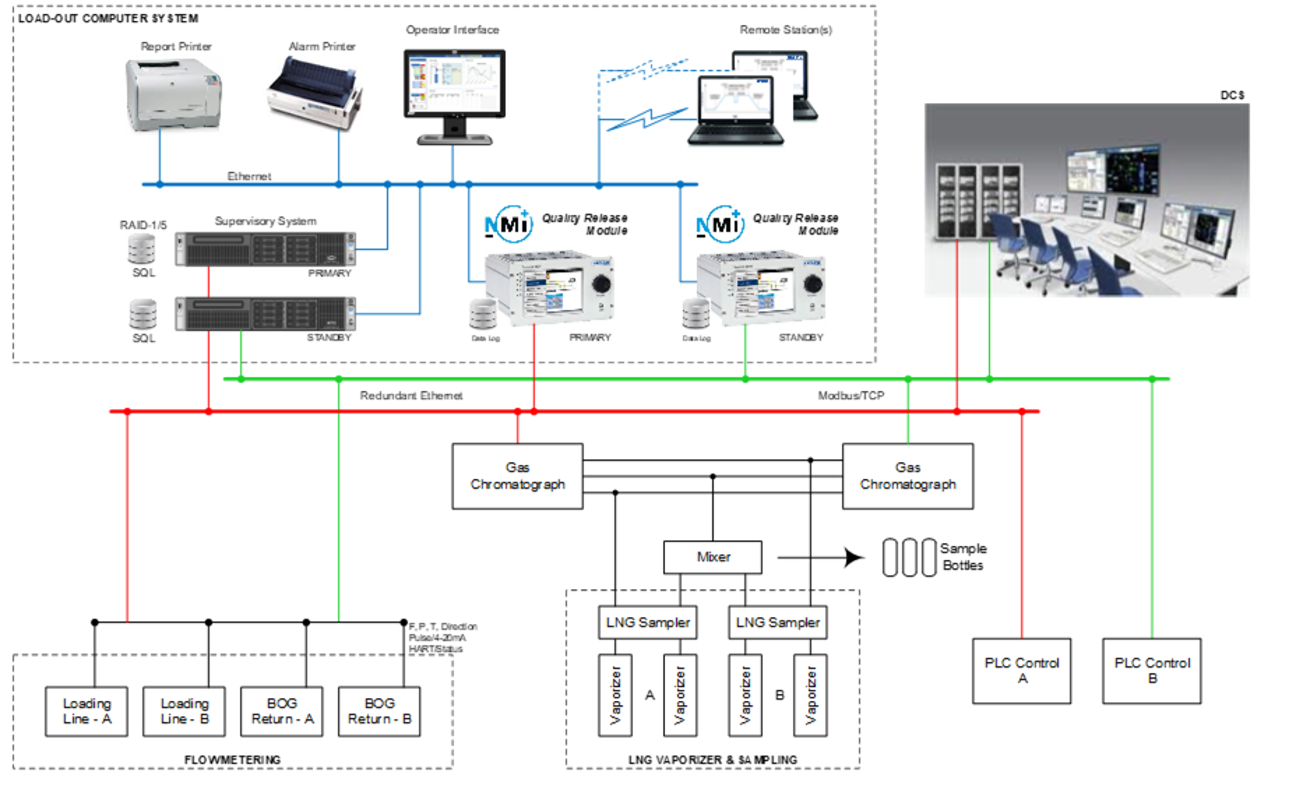

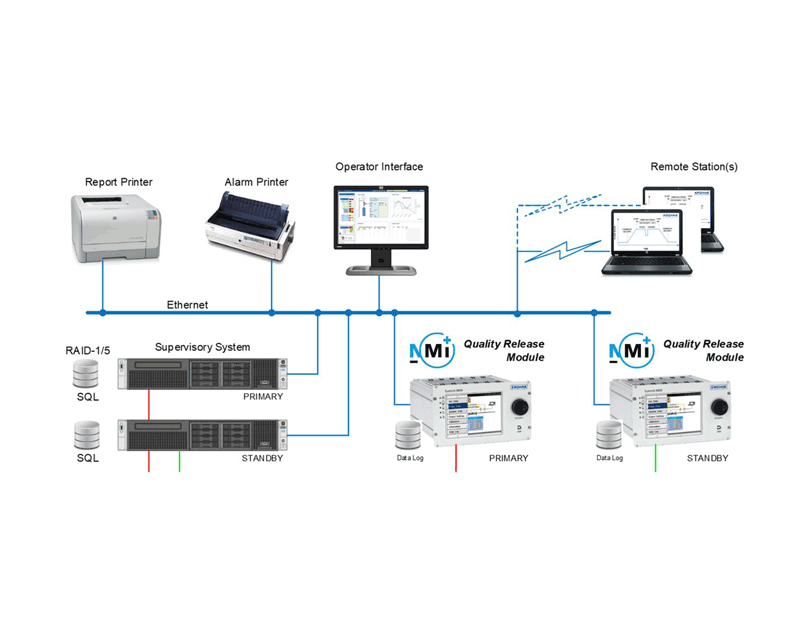

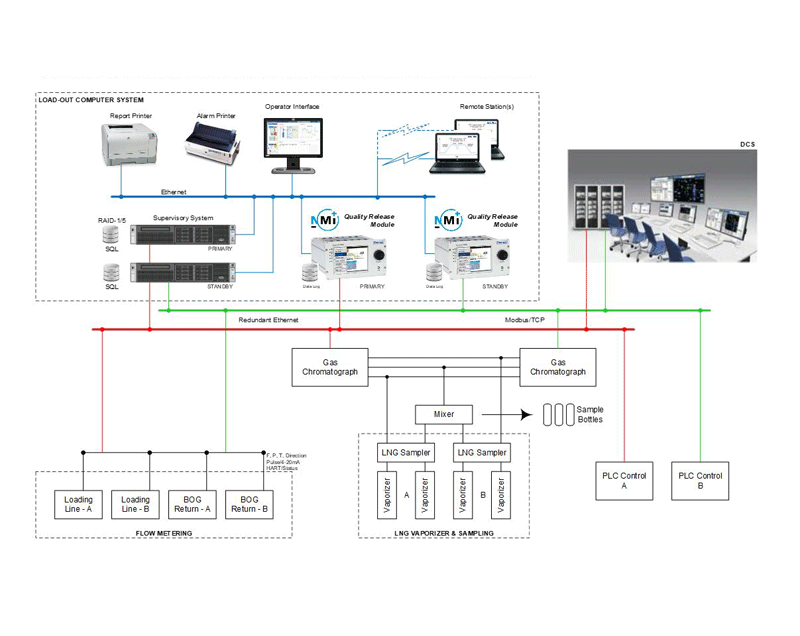

What does an L-QRS system look like?

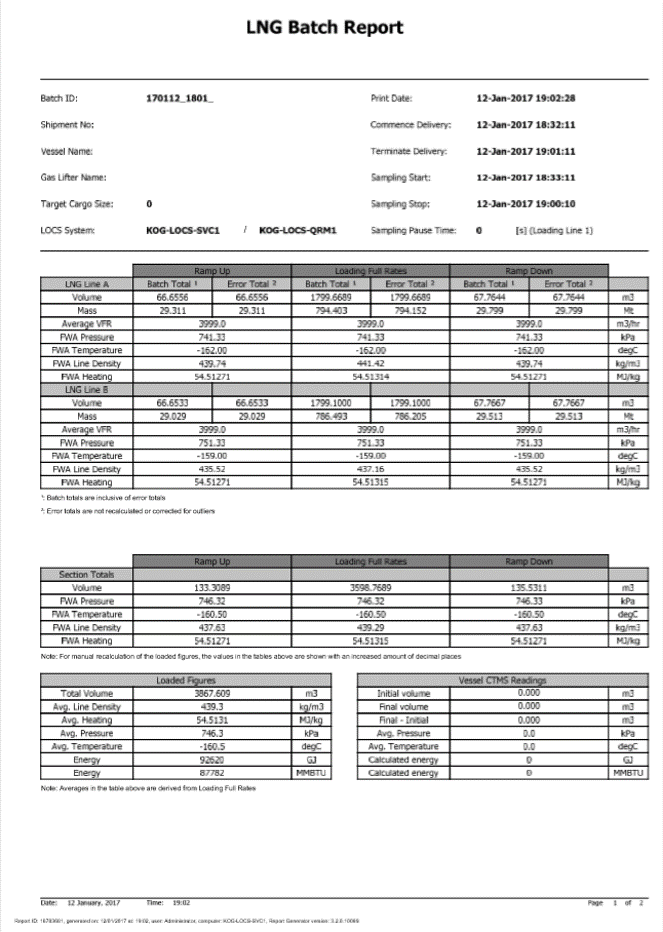

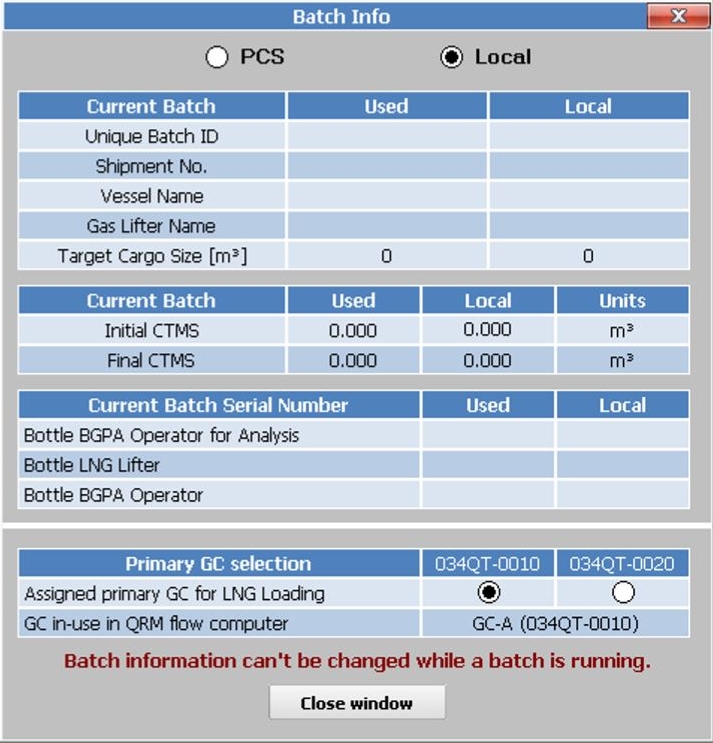

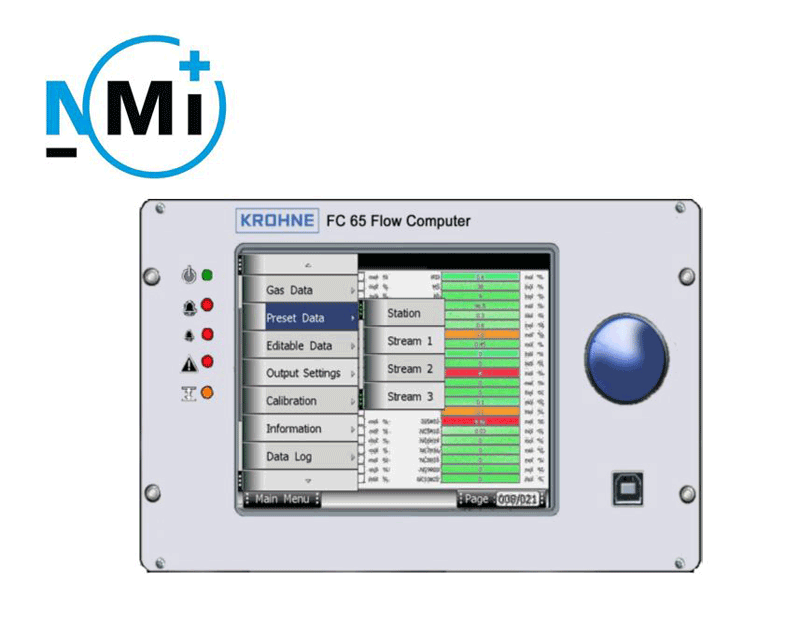

The L-QRS software system collects all the relevant information needed to determine the amount of energy transferred during (un)loading of an LNG-vessel. This information is processed in a flow computer for custody transfer measurement. The KROHNE SUMMIT 8800 flow computer provides the operator with real time monitoring of both the quantity and quality of the batch.

- The L-QRS can be installed in both new and existing LNG terminals

- The system is configured to suit the available infrastructure

- The system can be offered in combination with flow metering and sampling systems

- Designed specifically for mid-size and large liquefaction and regasification LNG terminals

Instant availability

Prevention of corrections through instant availability

Once the batch is completed, the system instantly provides the release of the quality certificates and the Bill of Lading. This is guaranteed, since the applied flow computer software is certified by NMi.

Due to the instant availability of both Bill of Lading and quality certificates, this system avoids costly retrospective corrections once the vessel has departed. This is guaranteed through different process field signals like FT pulses, pressure, temperature and PGC.

Data Processing

Fully automated information flows

The L-QRS system visualizes all the relevant information to the user. Possible human errors are eliminated in the data processing as the information flows are fully automated. This allows the user to observe the trending of process information, as well as displaying any alarms, which are logged. The whole system has a high level of cyber-security.

The standard displays, from overview to detailed line displays, are available on an operator station, which can be positioned in the control room, analyser house or a portable remote station.

Reporting of calculations

The software is extremely versatile and designed to integrate the key processes along the entire value chain, also including automated instrument validation and effective performance monitoring. Operational results are also optimised using predictive maintenance. The system presents calculations and reports for the following requirements:

- Total volume

- Flow-weighted average for gas composition

- Combined FWA for multiple loading lines

- Total energy based on L-QRS measured volume

- Total energy based on CTMS

- PGC Coverage

Cost reduction

Reduction of maintenance costs

Using the statistical benefits from the CalSys® software, the maintenance costs can be reduced – on average by more than 25%. Apart from process control and analyser validation, this management software provides effective performance monitoring of all the quality measurement instruments. Significant benefits can be achieved by the increased availability of critical analysers and instrumentation, auditable and traceable maintenance and calibration records, and cost savings on routine maintenance:

- Gas chromatograph validation (prior to each ship load)

- Long term evaluation using control charts

- Gas chromatograph calibration and Round Robin testing

- Pressure and temperature transmitter validation

- Vaporiser system validation (repeatability check)

- Instrument maintainability and availability monitoring & calculations

Compliance

Compliant to international standards and certified by NMi

To measure the amount of energy which is transferred during (un)loading of an LNG vessel, the software collects all the relevant information. Real time monitoring by an operator is then allowed both in terms of the quality and quantity of the batch. As the applied flow computer software is certified by NMi, once the batch is completed it immediately provides the quality release certificate and the Bill of Lading. The incorporated CalSys® functionality ensures full traceability of the instrumentation and optimises maintenance cycles.

Modules

Basic

Starts from a single flow computer only for LNG measurement incl. sampler and GC, no requirements for redundancy or BOG measurement, DCS used for reporting

Standard

A complete software system for both LNG and BOG metering in combination with automated quality measurements (like PGC) with extended diagnostics and reporting functionality, plus the Analyser Management System, using CalSys(R)

Advanced

Including dynamic metering, LNG sampling and quality measurements, this ensures full compatibility of all LNG loading components and allows extended diagnostics and one focal point in the project execution

| Advantages per configuration | Basic | Standard | Advanced |

|---|---|---|---|

| No ambiguity about the BoL, due to certified energy transfer calculations in compliance to international standards like; GPA 2172, ASTM D4784, ASTM E178, AGA8 and the GSPA | x | x | x |

| Less product give-away due to lower system uncertainties and outlier detection | x | x | x |

| Eliminate human errors copying measurement data between different systems | x | x | x |

| Full traceability and audible calculations and data processing | x | x | x |

| Instant availability of the bill of lading and quality certificates, avoids costly retrospective corrections once the vessel has departed | x | x | x |

| Reduces maintenance costs by an average of >25% using the benefits of CalSys® | x | x | |

| Increased availability of critical instruments (>95%) ensuring constant and reliable quality measurements | x | x | |

| Structured and consistent validation of analysers and instruments providing solid traceability and auditability | x | x | |

| Redundance system set-up; pay/check functionality | x | x | |

| Additional instrument diagnostics | x | ||

| Integral cost saving system design with one-stop-shop approach | x | ||

| Service level agreements available for the complete system | x |

Contact us

KROHNE Oil & Gas

Minervum 7441

4817 ZG Breda

www.krohne.com

Specialists from our dedicated Oil & Gas division are at your disposal to meet your process challenges, worldwide. Being an instrumentation supplier for the oil and gas industry for over 20 years, KROHNE have gained industry- and application-specific know-how that we have incorporated into our devices and solutions.