Reliable measurement of viscous edible oil with air entrainments and lower pressure drop

Advanced measurement solutions for edible oil production

Optimisation of hygienic processes through key technologies

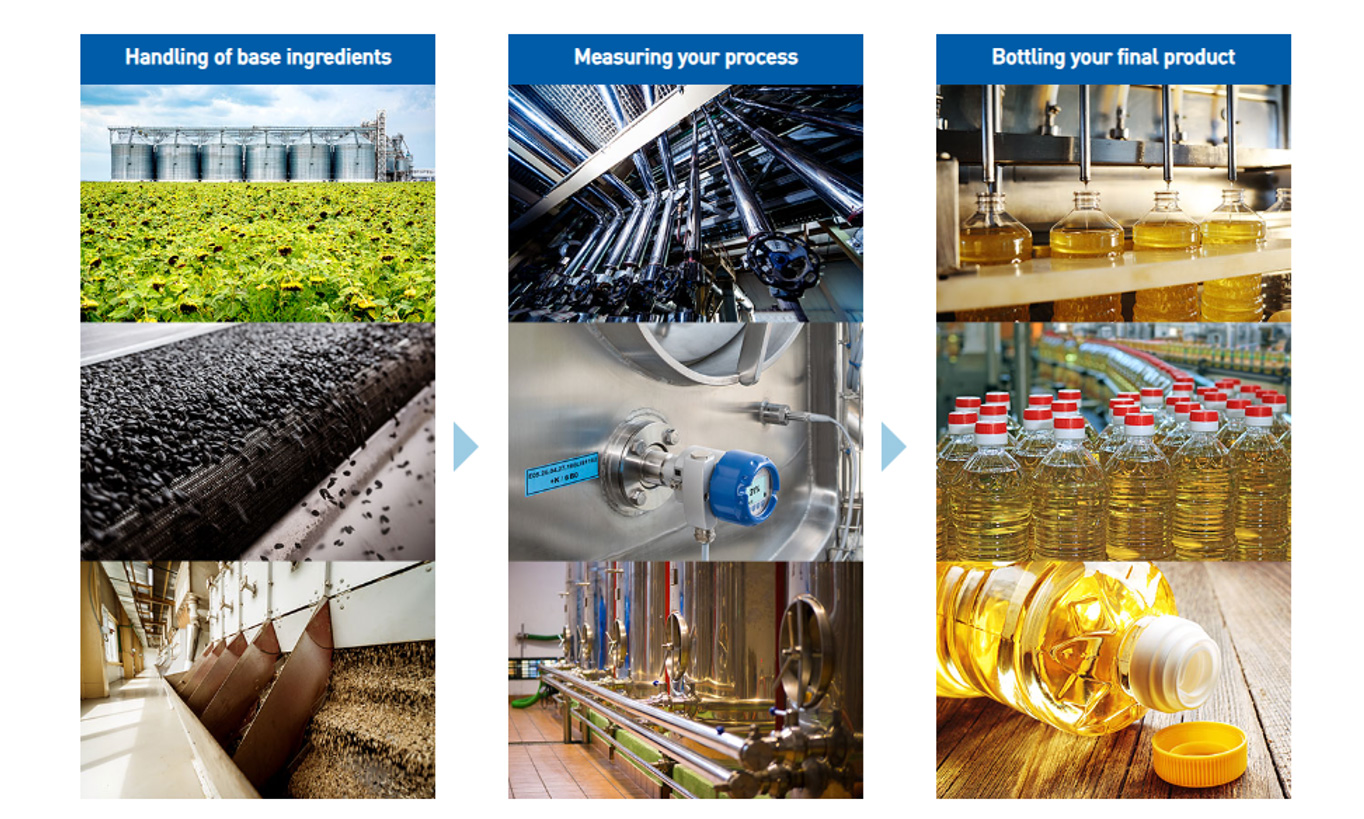

A high-quality product often means a challenging production process. Manufacturers of Edible Oil have special requirements, starting with the input logistics through to measurement accuracy – often down to the gram. KROHNE has a dedicated Global Industry Division which accepts these challenges and offers dedicated measurement solutions for the Food & Beverage industry.

In the edible oil manufacturing process, achieving high quality, safety and efficiency is the priority: this sets highly challenging demands on the measurement technologies used. Please accept our invitation to meet in person, or online, to discuss your process improvement potential. Let us help to enable the evolution of your manufacturing process with our industry and application know-how and high-quality products.

KROHNE – Specialised in the food industry of tomorrow

Specialists from our dedicated Food & Beverage division are at your disposal to meet your process challenges, worldwide. Being an instrumentation supplier for the Food & Beverage industry for over 20 years, we have gained industry- and application-specific know-how that we have incorporated into our devices and solutions.

Key technologies for the edible oil market

Reliable measurement of viscous edible oil with air entrainments and lower pressure drop

With higher viscosities comes high pressure drop. KROHNE features unique straight tube Coriolis mass flowmeters that benefit the smallest pressure drop. In combination with our EGM technology your process is optimised even when there’s entrained air present.

Increased lifespan with straight tube flowmeters

Abrasive fluids, as occurring in the production of edible oil, impacts pipe walls and erodes material – resulting in a reduced lifetime. The solution is a straight tube mass flowmeter where the fluid can pass through the pipe with no obstructions. Learn more about how straight tube mass flowmeters overcome these problems in this short video.

Radar measurement solutions for tanks with constant switching density

DP-level is still widely used within the process industry. However switching densities can give different results. Installing the latest FMCW Radars can neglect this issue. Enjoy a more accurate reading that is contactless to the medium and density independent.

Pressure transmitters with ceramic membrane: Fast reacting – temperature independent – no risk of leakage

Ceramic membrane pressure transmitters are advantageous over a metallic diaphragm when it comes to edible oil processes. No filling fluid can come into contact with the product. Furthermore the product features a low temperature influence and quick response time even at high process temperatures, 100% vacuum resistance and is highly robust.

Case studies

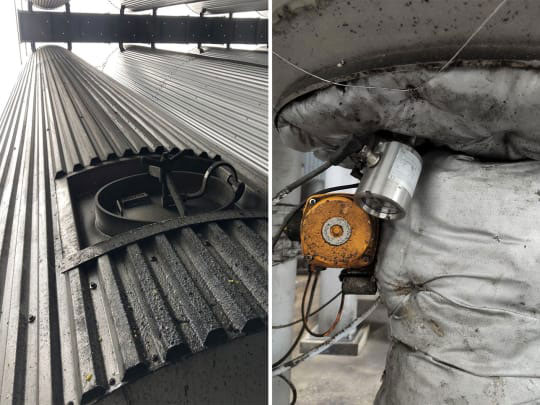

Hydrostatic level measurement in edible oil storage tanks

Application Report | Food & Beverage

- Reliable stock management of vegetable oils

- Rugged, fully welded gauge pressure transmitter for improved inventory monitoring

- Cost-effective replacement of faulty pressure gauges

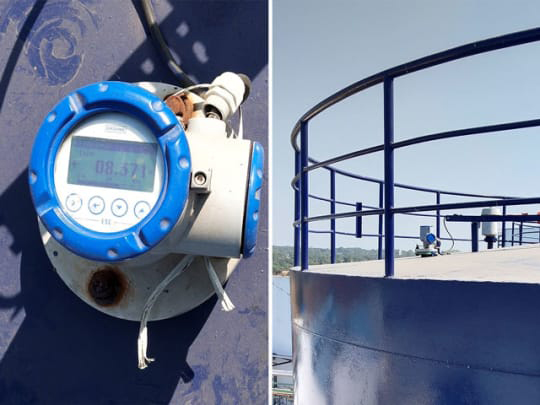

Level measurement of refined edible oil

Application Note | Food & Beverage

- Significant improvement of inventory control

- Use of non-contact radar level transmitters for accurate storage tank monitoring

- Continuous level measurement for stock management of vegetable oil

- Replacement of imprecise, irregular manual measurements

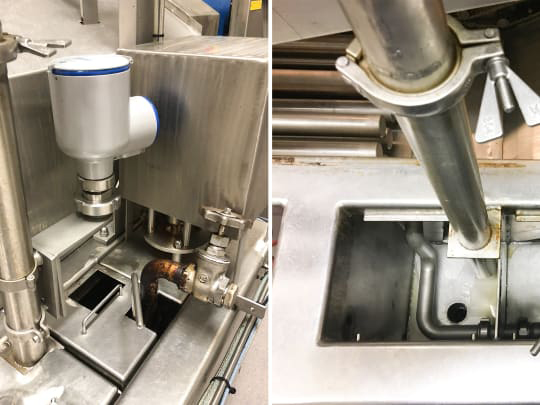

Level measurement of edible oil in a deep fryer

Application Note | Food & Beverage

- Monitoring frying oil level in the production of frozen food products

- Continuous, non-contact measurement of a hot and steaming liquid in a very small tank

- Improved frying conditions for an increased product yield

Equipping a mixing facility for edible oil with measurement technology

Application Report | Food & Beverage

- More accurate dosing of edible oils

- Traceability of product and energy consumption

- All instrumentation from one provider

- Technical support starting with project planning right through to after-sales care

Flow measurement in an oil mill

Application Note | Food & Beverage

- Determining the quantity of vegetable oil in production

- Mass flow measurement of a non-conductive liquid

- Control via PROFIBUS® PA interface

Our product portfolio for the food & beverage industry

Flow measurement

Flowmeters, flow controllers and flow accessories for the Food Industry

Level measurement

Transmitters, switches, indicators and accessories for level measurement

Pressure measurement

Process instruments for pressure and differential pressure applications

Temperature measurement

Assemblies, sensors, transmitters and accessories for temperature measurement

Process analytics

Sensors, assemblies, transmitters, systems and accessories for process analysis

Contact us

KROHNE – Specialised in the food industry of tomorrow

Specialists from our dedicated Food & Beverage division are at your disposal to meet your process challenges, worldwide. Being an instrumentation supplier for the Food & Beverage industry for over 20 years, we have gained industry- and application-specific know-how that we have incorporated into our devices and solutions.